Festo VTEM industrial motion terminal transforms the automation world

Festo VTEM industrial motion terminal transforms the automation world

January 15, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

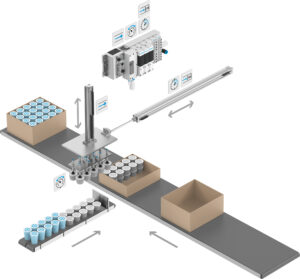

The Festo Motion Terminal (VTEM) uses software apps to set, control, and reconfigure all functions performed in both simple and complex pick-and-place solutions.

The groundbreaking VTEM industrial motion terminal from Festo Canada is the standard bearer for a new kind of pneumatics, challenging engineers to re-imagine processes. The digital pneumatics of the VTEM are transforming the automation world, delivering sweeping upgrades to pick-and-place, dosing, machining, parts handling, assembly, and other processes.

With the VTEM’s advantages, designers can conceive of virtually anything to improve automated systems, making them ready for Industry 4.0.

Enabling very quick changeovers

More precise and flexible than standard pneumatics are, digital pneumatics can perform many tasks more efficiently and cost-effectively on a life-cycle basis. VTEM software apps enable very quick changeovers for varying sizes and shapes of work pieces, products, or packaging; adjustments that typically take hours are reduced to minutes; and users can manage and reconfigure processes remotely. This industrial motion terminal has software apps and piezo valve technology that achieve function integration that eliminates the requirement for up to 50 downstream components.

The app enables a quick change in the tool function from suction-gripper head to gripper head with pin terminal as the piezo valves are usable as proportional or control valves. This makes the system like a re-programmable piece of hardware, as it adapts the software content to the individual application. With the VTEM, valves no longer have single functions; systems are like hardware pieces that are easy to re-program.

Autec, an Italian producer of automation systems for shoe and leather factories, incorporated this industrial motion terminal into a new machine for assembling credit-card slots for wallets. This machine controls the gluing of a leather and a silk piece; then a servo robot transfers the pieces to a leather-folding machine. This compact, space-saving solution glues and folds eight slots in 14 seconds, and it eliminates the typical error rate of manufacturing these items manually. It also makes optimum use of raw materials.

“Reconfiguring the Festo motion terminal is now extremely fast. Instead of ordering, installing, and reconfiguring additional proportional valves, all we have to do is activate an app,” said Autec project manager Ilario Barsacchi.

Trust the VTEM for similar results.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more