Festo launches fingerboard control system for oil and gas industry

Festo launches fingerboard control system for oil and gas industry

June 25, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

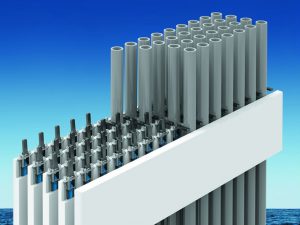

Festo’s new fingerboard latch control system, based on its revolutionary, software-driven VTEM Motional Terminal, offers enhanced safety and durability for management of off-shore drill rig tubulars.

One of the latest technological advances in the Festo Canada portfolio is a pneumatic fingerboard latching system for drill-rig tublars in the oil and gas sector. The technology core of this fingerboard control system is the VTEM Motion Terminal, the world’s first software-driven valve terminal.

This fingerboard latching system provides higher safety and durability, using the VTEM’s intelligent valves to control and monitor the fully locked or completely open position of every latch.

Easier to install and maintain

Using VTEM dispenses with the need for placing sensors and wire harnesses on each latch, making this next-generation fingerboard latch system easier to install and maintain than conventional pneumatic controls. This is a particular boon to management of operations in challenging offshore conditions – a safer, minimal-maintenance approach to latch control and monitoring.

This fingerboard control system operates by allowing the VTEM terminal to monitor cylinder air pressure and flow, thereby sensing and controlling the position of each latch from closed to fully open. The VTEM features internal sensors, pressure regulators, flow control, exhaust valves, and processing and communications capabilities. Users can see the measurements displayed graphically via a human machine interface, or HMI, and the data is also available to supervisory control systems. Every intelligent valve replaces two ordinary pneumatic valves for a 50 per cent reduction in the amount of components.

Festo has published a six-page white paper on this new fingerboard latching system, “Digital Pneumatics: Breakthrough in fingerboard control, safety, reliability”, which is available online. This white paper discusses the benefits of this application, such as cost and time savings in installation, less safety risk, reduced energy expenses, and higher reliability through preventive maintenance. Also included is information on what digital pneumatics means to industry, approaches to fingerboard operations, how the VTEM works, and the advantages of wireless, monitored fingerboard operations.

About the company

Founded in 1925, Festo is the world’s leading supplier of automation technology and technical education. Its global headquarters are in Esslingen, Germany.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more