Five facts about wire rope stretch

Five facts about wire rope stretch

September 14, 2015 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more

Subscribe

Free REDWIRE e-newsletter

Checking the stretch of wire ropes under load is an essential part of regular inspections recommended by Health and Safety Ontario. To help customers better understand wire rope basics such as stretch, Bergen Cable Technology, a leading wire rope and cable manufacturer, has provided a series of helpful explanations on its website.

To get started improving your knowledge of wire ropes, here are five facts to remember about wire rope stretch:

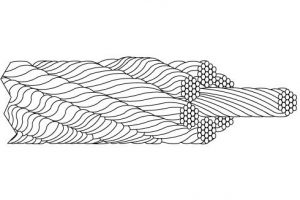

1. There are two ways wire ropes stretch when under load: elastic stretch and structural stretch.

Elastic stretch refers to stretching caused by elongation of the wires in the wire rope. It gets its name from the fact that the rope tends to return to its initial length once the load is released. Conversely, structural stretch is caused by the adjustment of wires and strands, lengthening of rope lay, and compression of the core. Both the elastic and structural stretch of a wire rope are affected by the weight of the load and the length of the rope. But there are a few other variables to consider when estimating elastic and structural stretch.

2. Elastic stretch is affected by wire rope area and material.

The elastic stretch is inversely proportional to the metallic area of the rope and the modulus of elasticity of the wire rope’s material. However, this only holds true as long as the load does not exceed the elastic limit of the rope. For example, the elastic limit of wire rope made from stainless steel is approximately 60 per cent of the breaking strength.

3. Structural stretch is affected by core size, lay lengths and rope construction.

The factors that affect the structural stretch of a wire rope include the size of the core, the length of the lays, and the construction of the rope. The amount of bending the wire rope is subjected to is another variable to keep in mind. When estimating the structural stretch of a wire rope, 0.5 per cent of the rope length can be used as a rough approximation.

4. The rate of stretching changes over time.

When a load is initially applied to a wire rope, the rope rapidly stretches as it adjusts to the operating conditions. After that initial phase, the stretching slows significantly and remains low for the majority of the rope’s lifespan. When the rope approaches the end of its service life, the rate of stretching increases due to wear and fatigue.

5. The diameter of wire ropes shows when replacement is needed.

In recommendations for wire rope inspections, Health and Safety Ontario suggests checking the diameter of wire ropes to identify stretching. The guidelines say that a six-strand wire rope should be replaced if stretching causes a difference in diameter greater than 1/16.

Visit the Bergen Cable Technology website to learn more about wire rope or the company’s manufacturing capabilities.

Share

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more