Five factors to keep in mind when implementing conveyor systems

Five factors to keep in mind when implementing conveyor systems

April 6, 2017 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more

Subscribe

Free REDWIRE e-newsletter

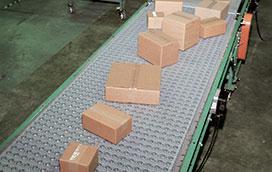

Norpak Handling can provide all types of conveyor systems, from simple gravity conveyors to complex systems with accumulation and sortation capabilities. When developing a new conveyor system, or improving an existing installation, there are some basic, but essential, considerations to keep in mind.

What is your product?

The exact product or mix of products to be conveyed is an important factor in selecting the right conveyor. That includes product size, weight, packaging type, whether it’s liquid and may shift during transport, and even the colour of the packaging. Packaging colour can be important because some scanning devices cannot read certain materials.

What are your expectations?

When customers are discussing their project and application, it is important to let Norpak Handling know precisely what they expect from the equipment. That might include things like reducing the labour force, adding floor space, improving ergonomics, or speeding up production by 50 per cent.

What is the environment?

Regardless of the quality of equipment, if it is not designed for the environment where it is used, problems can arise. For this reason, it is important to consider whether the application involves dusty environments, oil spillage or fork truck traffic.

What is the project deadline?

Although deadlines are often discussed as the bid is finalized, they should be considered early in the process. That’s because it is easier to work backwards from a deadline than to try to squeeze it in. When setting deadlines for new buildings, allowances for delays due to weather should be kept in mind. In addition, all parties involved in the project should be made aware of deadlines.

What is the plan for after the purchase?

It is also important to think about what will be required after a new conveyor system is in place. For instance, consider whether a training program is needed for employees on the new equipment. Another thing to consider is whether you want to track product throughput to compare it to the project expectations.

To learn more about how to get the ideal conveyor system, visit the Norpak Handling website.

Share

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more