How to extend the life of your bearings

How to extend the life of your bearings

December 5, 2014 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

Premature bearing failure is a real problem. Bearings are at risk whenever seals allow lubricant leakage or contaminant intrusion into the housing. Until now, there has been no comprehensive solution — only partial solutions.

Standard radial lip seals, for example, are an acceptable solution for most shaft sealing requirements; however, they have two drawbacks in some applications. First, standard radial lip oil seals are designed for one-way performance. They keep lubricants in, but they do not keep contaminants out. Second, they ride on the shaft causing wear on both the shaft and the seal. Eventually, this causes lubricant leakage.

Even though labyrinth seals were developed to address these problems, they have performance weaknesses. Not only are many labyrinth seals costly and complicated, they also allow some contamination to reach lubricants. The use of metal in labyrinth seals results in costly designs, close tolerances and difficult installations. Some manufacturers offer two-piece, non-unitized labyrinth seals. However, with one exception, unitized labyrinth seals have at least three components and up to four O-rings.

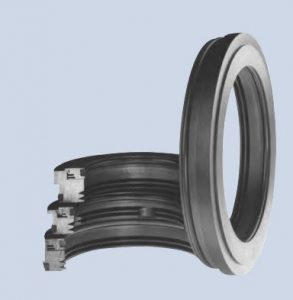

JM Clipper uniquely designed ProTech labyrinth seals to protect bearings with zero lubricant leakage and total exclusion of contaminants. Only ProTech is based on a simple, unitized, two-piece PTFE design with only two O-rings. Only ProTech has four unique designs — standard flanged, non-flanged, multi-port and split pillow block — that provide outstanding performance and lower cost.

There are many benefits to the simplified design of ProTech, including fewer working components; easy installation; accommodates greater shaft misalignment and eccentricity (up to 0.020 inches TIR); easier to retrofit in standard bore housings; self-aligning; requires no lubrication; and it’s non-contact, meaning no wear and no heat build up.

It is suited for many applications — from chemical resistance and food processing, to pumps, motors and gearboxes.

For more information on ProTech labyrinth seals, and how to extend the life of your bearings, contact Daemar Inc.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more