Expert advice from John Brooks Company stops plant’s heat-exchanger leaks

Expert advice from John Brooks Company stops plant’s heat-exchanger leaks

December 15, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by John Brooks Company Limited

John Brooks Company Limited: Fluid Handling Solution providers since 1938. For over 80 years, John Brooks Company has pr... Read more

Subscribe

Free REDWIRE e-newsletter

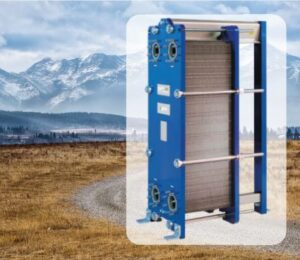

A sour-gas plant had a faulty heat exchanger.

John Brooks Company Limited has a long history of customer success stories to recommend its services. A recent example was a customer in the Rocky Mountain foothills that took over a sour-gas plant that had been operational for decades – and discovered that a heat exchanger in the plant had been leaking.

After conducting an onsite audit, an expert from John Brooks Company helped to solve the leak issue for this customer – while also boosting efficiency and production.

A plate pack shift

The plant staff conducted scheduled maintenance on two redundant heat exchangers that had seemed to be running without issues for years. It turned out that one of the units had leaked within a month of maintenance startup, which concerned the company. To get to the source of the problem, the plant got in touch with a John Brooks Company application expert.

This heat-exchanger expert, Ross McGowan, paid a visit to the plant to inspect the leaky heat exchanger. He removed the unit from the facility and brought it to the service centre for a thorough review and inspection. Following these, McGowan compiled a report and discussed its contents with the customer. The cause: the exchanger had suffered a plate pack shift, initiated by liquid flow and operating procedures during an extremely cold period.

This discussion between McGowan, the plant process engineer, and the operations personnel determined that plant piping had not been properly balanced between the two redundant heat exchangers. In addition, operations revealed that the failing unit had been causing trouble for years, so they had been more careful with it during startup. This resulted in a broader talk between the engineering and operations staff, which eventually begot improvements in maintenance and operations – and even a full design review of the piping layout.

The customer made all of the recommended changes. Today, this organization continues to work with John Brooks Company, trusting the latter as a technical partner and solution provider. Solutions like this are typical.

To learn more about this case study and others, visit the website.

To learn more, contact John Books Company.

Share

Posted by John Brooks Company Limited

John Brooks Company Limited: Fluid Handling Solution providers since 1938. For over 80 years, John Brooks Company has pr... Read more