EXAIR’s Cold Gun: Cool innovation tackles machining heat with extra safety

EXAIR’s Cold Gun: Cool innovation tackles machining heat with extra safety

December 29, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Exair LLC

EXAIR’s compressed air products are designed to improve the overall efficiency of your operations. Intelligent Compresse... Read more

Subscribe

Free REDWIRE e-newsletter

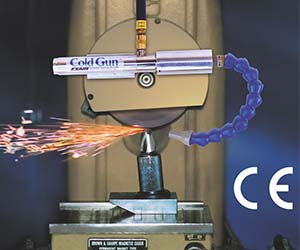

The new CE-Approved Cold Gun by EXAIR

EXAIR LLC keeps its wide North American customer base satisfied, productive, and profitable with a portfolio of industrial compressed-air equipment that is always expanding with new innovations. The latest addition to the EXAIR family is the new Cold Gun Aircoolant System, which serves as a low-cost alternative to expensive mist systems.

An instrument that meets the requirements of the European CE safety standard, this Cold Gun Aircoolant System produces a cold, quiet stream of air to reduce heat buildup on machining operations.

No health issues for employees

The EXAIR CE-Approved Cold Gun also eliminates the ongoing expenses associated with the purchase, filtration, and disposal of liquid coolants, and there are no health issues for employees stemming from breathing in airborne coolants or slipping on wet shop floors. The EXAIR team has made the device non-adjustable, to prevent any freezing up during continuous use, and it comes highly recommended for machining tasks that involve tool sharpening, drill and cutter grinding, milling, drilling, surface grinding, band sawing, plastic machining, and plunge and form grinding.

While quickly and quietly converting compressed air into cold air, the CE-Approved Cold Gun prolongs tool life, prevents tool burning, eliminates wheel loading, and creates air that is 30 degrees Celsius below the supply-air temperature. The device also meets the noise and pressure requirements of the United States Occupational Safety and Health Administration, as well as the rigorous safety, health, and environmental standards of the European Union.

The instrument incorporates a stainless steel vortex tube to convert an ordinary supply of compressed air into a cold stream at one end and hot exhaust at the other. There are no moving parts to wear out, and the muffler on the hot air exhaust lowers the noise level to a quiet 70 dbA. A magnetic hose offers simple mounting and portability, while a flexible ball and socket hose that holds its position directs the cold air to the point of use.

Based in Cincinnati, EXAIR LLC has designed and produced an unmatched range of industrial compressed-air solutions since 1983. Among the examples are air guns, vacuum generators, and static eliminators.

Share

Posted by Exair LLC

EXAIR’s compressed air products are designed to improve the overall efficiency of your operations. Intelligent Compresse... Read more