Dorner Precision Move Pallet Systems feature industry-leading technology

Dorner Precision Move Pallet Systems feature industry-leading technology

September 4, 2015 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Wecon Systems Ltd.

Welcome To Wecon Conveyor Systems. We are a complete single source Material Handling Systems Integrator providing convey... Read more

Subscribe

Free REDWIRE e-newsletter

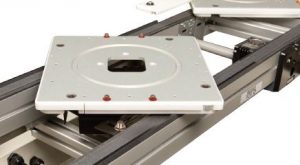

Dorner has a mission — to provide its customers with a system they can depend on to move product with precision and speed. That mission is accomplished with the company’s new 2200 Series Precision Move Pallet Systems — innovative, modular, dual-belt conveyor pallet systems for assembly automation.

There are many features that make the innovative 2200 Series stand out:

- Added capacity: Timing belt conveyors provide added load capacity in a small platform. With speeds up to 34 metres a minute, the system has a non-accumulating conveyor load capacity of 500 pounds, an accumulated load capacity of 250 pounds, and a pallet capacity of 30 to 70 pounds.

- Innovative lifting modules: The modules have lift and locate capability, with an adjustable height lift from the centre of the conveyor. It offers 200 pounds of lift capability at 90 psi. The modules also have a lift and rotate capability, with a pneumatic lift from the centre of the conveyor. They provide pneumatic rotation with adjustable positioning, and an adjustable rotation angle of 90 to 180 degrees. The system also lifts and transfers to change product orientation.

- Quick belt change: The system offers quick belt change without the need to remove the conveyor from the system. The dual-belt conveyor’s timing belt is 25-mm wide, with a five-mm pitch. Standard or static conductive belting is available.

- Simple powered corner modules: On 90-degree corners, the system maintains product orientation through the turn, and includes a 24 VDC drive mechanism to drive the pallet around the corner. On 90-degree corner and merge modules, an inside guide is mounted to pneumatic cylinders to transfer the pallet around the corner. A straight guide with pneumatic cylinder is mounted across a perpendicular conveyor to guide pallets straight through the merge area. This module also includes a 24 VDC drive mechanism to drive the pallet around the corner.

- Pin tracking system: The pin tracking system provides a simple and cost-effective method of tracking pallets through turns. It is used on 90-degree corner and 90-degree corner and merge modules.

- Time saving: Dorner’s online configurator engineers simple to complex configurations in minutes. The tool delivers a complete 3D assembly model for instant validation of fit.

- Fast delivery: Dorner sets the industry standard for rapid delivery. Conveyors and automation modules are available in 20 days or less.

Designed for medium- to large-sized part movement, the 2200 Series is available in widths from 160 to 480 mm, and lengths up to 7.5 metres.

Wecon is proud to carry the 2200 Series Precision Move Pallet Systems from Dorner, a recognized leader in precision conveyors for nearly 50 years. Based in Mississauga, Ont., Wecon offers cost-effective solutions to meet its customers’ conveyor equipment needs.

Share

Posted by Wecon Systems Ltd.

Welcome To Wecon Conveyor Systems. We are a complete single source Material Handling Systems Integrator providing convey... Read more