Denso high-build coal tar epoxy offers powerful protection against damage

Denso high-build coal tar epoxy offers powerful protection against damage

January 6, 2022 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Denso North America Inc

Worldwide Suppliers Of Anti-Corrosion, Waterproofing & Sealing Systems For Pipeline Coatings, Steelwork Protection,... Read more

Subscribe

Free REDWIRE e-newsletter

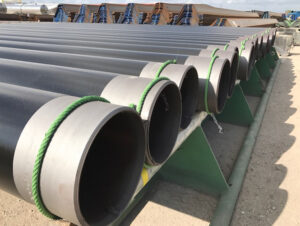

Protal 600 CTE is perfect for pipelines.

Anti-corrosion solutions are one specialty of Denso North America, such as liquid coatings for pipelines and infrastructure. One effective product is Protal 600 CTE high-build coal tar epoxy. This is designed for long-term protection of steel and concrete substrates, against water, wastewater, seawater, alkaline water, and acidic water corrosion. Recommended scenarios for this solution include coating steel piles, sheet piles, lock gates, reservoirs, non-potable water pipelines, treatment or storage tanks, bridges, and other aggressive applications.

For concrete and steel surfaces

Users can apply this two-part, high-build coal tar epoxy by spray or brush as a single- or two-coat system, plus a polyamide with high chemical and abrasion resistance. Among the benefits of using Protal 600 CTE:

- high resistance to sea, waste, alkaline, acidic, and pure water;

- high impact resistance;

- high flexibility, hardness, and adhesion;

- no primer required;

- high build of up to 600 microns in one coat; and

- compatibility with cathodic protection systems.

Protal 600 CTE works on concrete and steel surfaces. Users must cure concrete surfaces for 20 days at a temperature of 25 degrees Celsius and 50 per cent relative humidity. Denso recommends preparing concrete surfaces according to ASTM D428 and ASTM D4259 and filling and repairing all voids.

When coating steel surfaces, all contaminants should be removed from the surface, as oil, dust, and grease can interfere with adhesion. The surface should also be free of projections, sharp edges, and high points, and fillets must be ground smooth. Surfaces should be prepared by grit-blasting to a clean, near-white finish with SSPC-SP 10 or NACE No. 2 for immersion service, or with SSPC-SPC6 or NACE No. 3 for non-immersion service. For a 50-to-100-micron anchor profile, appropriate angular abrasive should be used.

To apply Protal 600 CTE by spray, it is wise to use a single-leg airless unit, a minimum of 60:1 airless pump. A wet-on-wet spray technique is necessary to achieve a build of 280-660 microns, and coating thickness should be measured with a wet-film thickness gauge. For repairs, surfaces should be roughened about 2½ centimetres around repair areas with 60-to-80-grit sandpaper.

For more information, contact Denso.

Share

Posted by Denso North America Inc

Worldwide Suppliers Of Anti-Corrosion, Waterproofing & Sealing Systems For Pipeline Coatings, Steelwork Protection,... Read more