Daemar’s advice on designing equipment to get better seal performance

Daemar’s advice on designing equipment to get better seal performance

February 15, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

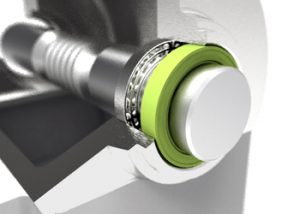

Designing bores and shafts properly will extend the lifespans of Daemar seals.

Daemar Inc. supplies an unparalleled portfolio of essential components for Canadian industry, including a broad range of sealing components. For these seals to function at maximum ability, the two components with which they interact – the bore and the shaft – must be designed appropriately. This optimizes seals’ performance and extends their operational life.

In a blog post by Daemar, the company offers its expert tips on how to design bores and shafts to get the best performance from sealing components.

Adequate lead in chamfer

According to Daemar, bores should have adequate lead in chamfer and proper tolerance to enable the right press fit of the seal’s outer casing after installation. This prevents leaks between seals and bores, while eliminating any seal rotation or movement during operation. Shafts should also be manufactured with proper lead in chamfer, plus appropriate diameters and surface finish. Minimizing shaft movement and misalignment not only improves performance, but also limits seal lip wear.

One should consider the following traits when designing bores: material, hardness, finish, lead-in chamfer, and tolerance. Steel and cast iron provide a good surface for accepting metal and rubber O.D. seals. Bores should be hard enough to withstand the seal’s O.D., and the finish should be 0.8 to 1.6 μm Ra for metal O.D. seals or 2.5 to five μm Ra for rubber ones. The lead corner should be chamfered and bore-free.

For shafts, Daemar recommends the following design considerations:

- Material. Sealing components perform best with stainless steel or medium-to-high carbon steel.

- Hardness. Minimum Rockwell C45.

- Finish. Use plunge grinding to attain a surface roughness from 0.2 to 0.8 μm Ra.

- Lead-in chamfer. Shaft ends must be chamfered; the corners must be rounded and free from burrs and sharp edges.

- Tolerance. Check the shaft tolerance tables on Daemar’s website.

- Eccentricity. Shaft-to-bore misalignment and dynamic runout can affect seal performance. Misalignment refers to the distance between the center of shaft rotation from the bore centre, while dynamic runout is two times the distance of displacement between the shaft centre and the actual rotation centre.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more