Daemar V-rings are versatile and perfect for shaft-seal applications

Daemar V-rings are versatile and perfect for shaft-seal applications

February 28, 2022 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

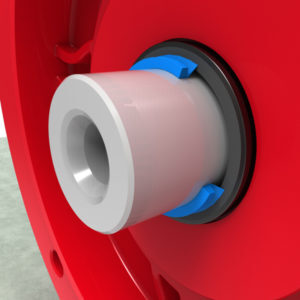

Four V-ring series are available from Daemar.

Among the essential components for industry that are available from Daemar Inc. are four series of V-rings. These are solid, axial shaft seals that employ centrifugal slinger action to stop dirt, moisture, and other contaminants from entering oil seals and their housing; they also keep the lubricants in.

V-rings are recommended for pressure-less application use. They are common in rolling mills, agricultural equipment, and electric motors.

Stretch easily over flanges

This component functions by rotating with the shaft and holding itself in position by its flexible fit on the shaft. The contact between the seal lip and counterface induces the seal. Although V-rings work well on their own, customers typically combine them with other seals, including radial shaft seals, or use them as pre-sealing material for bearings.

There are many advantages to using these versatile rings. They reduce wear in oil seals, shafts, and bearings, and they have minimal torque drag and heat buildup, without needing expensive counter-surface preparation. V-rings operate nicely in dry applications, on spinning or oscillating shafts, and at speeds higher than 3,000 feet per minute.

Because V-rings are rubber and elastic, users can easily stretch them over flanges and other components for simple installation, with little equipment disassembly. The lip presses against the counterface with minimal pressure or friction. The wide toleration allows one V-ring to fit varying shaft sizes and resolve shaft misalignment and eccentricity, while its durability ensures long work life and no installation damage.

Daemar V-rings come in Buna N and Viton, and units made of NBR and FKM have wide temperature ranges and offer good chemical resistance to many greases and mineral oils. The following four models are available from Daemar:

- VA. Standard V-ring with a straight back for shaft from three millimetres to two metres. Perfect for conveyor rollers and appliances.

- VS. Recommended for high-speed applications, with its angled back. Popular in the farming and automotive sectors.

- VL. Narrow cross-section for limited spaces. Ideal for pillow-block applications.

- VE. Heavy-duty design for large-diameter tasks. Frequently used as a dirt/water excluder seal in rolling mills.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more