Daemar offers expert advice on how to select the right shaft seals

Daemar offers expert advice on how to select the right shaft seals

February 27, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

Selecting a shaft seal requires careful consideration.

Respected across the country for an unsurpassed inventory of essential components for industry, Daemar Inc. is more than just a great supplier. The company is also a team of experts who help customers to find the products that best fit their applications, and its website offers useful information. For example, visitors to the site can learn Daemar’s expert advice on shaft seal selection – how to extend shaft-seal life with careful choosing.

Critical factors to consider

Informed selection of rotary shaft seals is a major influence in bearing longevity and reduction of maintenance costs for gearboxes, pumps, and motors. Not only do these seals retain system lubricants to enable operation with optimal levels of lubrication; they also prevent contaminants from entering systems and causing bearings to fail.

Manufacturers must assess the demands of their operating environments before shaft seal selection, according to Daemar. Among the critical factors to consider are the following:

- contaminants in the work environment;

- fluid compatibility with the lubricant and process liquid;

- geometry of the shaft and housing bore;

- operating temperature for the seal;

- pressure;

- shaft eccentricity and surface speed;

- shaft hardness and surface finish; and

- type of shaft motion.

Next, the customer should determine the specifications for the seal’s individual elements, based on application information. The shaft seal must create a seal between the rotary and stationary components or between components in relative motion to accomplish the intended goal.

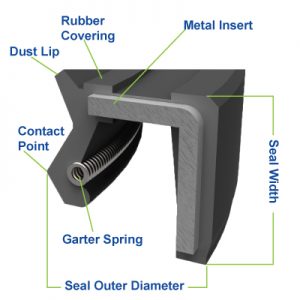

Another vital consideration in shaft seal selection is material and design. Each component contributes to overall effectiveness. Casing provides structure and rigidity while creating a static seal with the bore, usually built of carbon steel, and the sealing lip and garter spring maintain a dynamic seal with the shaft. Choose the most suitable elastomer according to the workplace assessment. Friction and wear can be minimized with the right spring and geometry in the lip.

Finally, after selection, the user must learn proper installation procedure to avoid seal failure. The shaft and bore must have lead-in chamfers and be devoid of sharp edges and burrs.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more