Daemar helps customers design equipment for optimal seal performance

Daemar helps customers design equipment for optimal seal performance

March 27, 2017 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

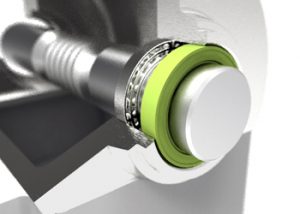

Daemar offers a broad selection of shaft seals that are designed for high performance. To take full advantage of this performance, however, it is essential that bores and shafts are designed properly.

For instance, the bore must have adequate lead-in chamfer and appropriate tolerancing to ensure a proper press fit of the seal’s outer casing. In addition, the shaft needs to be manufactured with the right lead-in chamfer, diameter and finish. When all of these design elements are correct, leakage is prevented, seal movement is eliminated, performance is increased, and operating life is extended.

Daemar offers customers help with these equipment design principles by posting technical resources on its website, including bore and shaft design guidelines.

Bore design

Some of the main considerations involved with designing bores to optimize seal performance include:

- Material – Bore housings are typically made from steel and cast iron because they offer a good surface for both metal and rubber O.D. seals.

- Hardness – Bores should be hard enough to withstand the seal's O.D.

- Lead-in chamfer – The lead corner (or entering edge) of the bore should be chamfered and burr-free.

- Bore tolerance – Tables are available on the Daemar website.

Shaft design

Some things to keep in mind when designing shafts include:

- Material – Seals work best on stainless or medium to high carbon steels such as SAE 1035 or 1045.

- Hardness – Shafts should be hardened to a minimum of Rockwell C45.

- Lead-in chamfer – The shaft end should be chamfered with rounded corners, no sharp edges, and no burrs. This will avoid damaging seals during assembly.

- Shaft eccentricity – The two types of eccentricities that can hamper seal performance are shaft-to-bore misalignment and dynamic run-out.

These are only a few of the many ways to assure proper seal performance. Visit the Daemar website for more information. The company offers a wide selection of seals such as oil seals, V-rings, high-pressure seals and more.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more