Daemar bearing isolators extend operational life with no lubricant leakage

Daemar bearing isolators extend operational life with no lubricant leakage

November 21, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

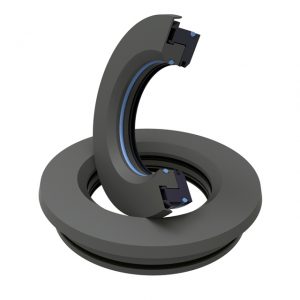

Daemar offers a selection of bearing isolators.

Daemar Inc. remains a leading supplier of essential industrial components, and that includes a wide range of shaft seals – all of which offer the quality and performance that engineers need and high savings in cost of ownership. This group includes a good variety of bearing isolators, or Protech seals, built to protect bearings with no lubricant leakage to the atmosphere whatever and with total exclusion of contaminants from the housing.

Fourteen different designs available

Daemar’s line of bearing isolators is built from a unique technology that has resulted from years of development, to offer complete bearing protection. The operational lives of bearings can diminish significantly from even a small amount of dirt or water. While lip seals have been designed to keep all lubricants in, they do not always succeed at keeping out contaminants, so bearing isolators provide a better solution.

Daemar bearing isolators are based on a unique, simple, unitized, two-piece design that is normally produced in chemical-resistant PTFE. The Protech product range includes a full family of complementary designs that offer excellent performance for a variety of applications. Fourteen different versions are available, including Types FS and FN, which are recommended for applications with pressurized, flooded, or sealing bearing housings; these two isolator types have internal lip seals, which enhance the components’ abilities to prevent leaks and keep out contaminants.

These shaft seals are built with high-grade PTFE composites that enable them to perform a wide range of operating capabilities, including applications in extreme temperatures and chemical environments. The isolators are common substitutes for existing sealing devices, with no alterations of equipment required. Alternative PTFE fillers make them suitable for use in food processing and pharmaceuticals, and they can also lengthen equipment lifespans in pulp and paper, oil and gas, and mining.

In addition to bearing isolators, Daemar also distributes numerous types of industrial seals, as well as V-rings, end covers, and sanitary gaskets. This is the place to go for the widest inventory of shaft seals.

With 45 years of success behind it, Daemar offers top products and exceptional customer service.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more