Custom Foam Systems maintains excellence through continuous improvement and quality

Custom Foam Systems maintains excellence through continuous improvement and quality

June 24, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Custom Foam Systems Ltd.

An Industry Leader In Engineering And Manufacturing Of Fabricated And Moulded Polyurethane Foam Components For A Diversi... Read more

Subscribe

Free REDWIRE e-newsletter

With strict production processes, CFS meets all goals.

For close to half a century, Custom Foam Systems Ltd. (CFS) has been a leading Canadian source of custom foam solutions for manufacturing applications. The company has a proven track record of performance and reliability. One of the ways that the company maintains its reputation for excellence is through a devotion to continuous improvement and high quality. With its stringent processes and team-based approach, CFS continues to outdo competing producers in this field.

Meeting targets with exemplary workmanship

CFS has modelled its world-class, lean manufacturing, production, and management systems after the Toyota Production System and the Hoshin Kanri approach to operations. Guided by international quality standards, these systems help CFS to meet all production targets with exemplary workmanship and constant quality, aiming for zero defects and 100 per cent punctuality.

The company roots its support strengths with custom product development in three unique processes: Advanced Product Quality Planning, the Production Part Approval Process, and Failure Mode and Effect Analysis. These processes help CFS to gain efficiencies, reduce waste, and offer better levels of service, satisfaction, and added value in custom foam solutions. A few ways in which the company meets its mandate every day for constant improvement:

- holding daily pre-shift and production performance meetings with all staff, including executive management;

- conducting hourly tracking of production output and testing quality to meet goals;

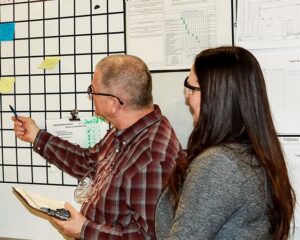

- communicating progress regularly through division team accountability and visual measurement boards;

- assigning ongoing action items to specific employees to complete; and

- reporting both hourly and daily resolutions.

The Hoshin Kanri approach is a major part of CFS’ processes. This is a method to manage or deploy strategic direction to help ensure that all workers know that they are all working as a team in the same direction, to improve the chances of success in every goal. This system helps to clarify roles, eliminate waste, solve issues, and contribute to overall success.

With constant improvement and quality processes, CFS proves itself to be adaptable, resourceful, and highly skilled in creating custom foam solutions. This company is committed to meeting customer needs and exceeding expectations.

To learn more, contact CFS.

Share

Posted by Custom Foam Systems Ltd.

An Industry Leader In Engineering And Manufacturing Of Fabricated And Moulded Polyurethane Foam Components For A Diversi... Read more