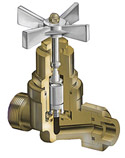

CPV seals up the o-ring competition: say hello to our 6000 PSI o-seal valve series

CPV seals up the o-ring competition: say hello to our 6000 PSI o-seal valve series

September 16, 2014 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by CPV Manufacturing

Since 1915 CPV has provided leadership in the development of leak proof valves and fittings. Our leading edge engineerin... Read more

Subscribe

Free REDWIRE e-newsletter

Oh what a difference an o-ring makes. Whether designed as a water seal valve or a valve seal eliminating dry air, o-rings are the humbly yet hugely significant piece of gasketing material designed to seal objects in or out.

O-rings are a type of circular seal or gasket used in commercial and industrial machinery demanding a right and tight seal for critical closure applications.

Also referred to as o-seals, o-rings need to provide infallible sealing protection against air and fluid loss or escape to piping, tubing and joints connected inside large transport machinery, for example, from airplanes to rockets.

CPV Manufacturing is on board with helpful proper installation and sealing advice for our 600 PSI W-O-G service o-seal valve. For more detailed explanation with images of this model, as well as all of our popular o-seal valves, visit us at www.cpvmfg.com.

Go install CPV’s 6000 PSI o-seals to fittings and valves the right way

To ensure the proper and efficient installation of fittings to an o-seal, metal surfaces need to be in prime condition, alignment and contact in order to prevent o-ring extrusion (or malformation) under extreme pressure in sealing applications.

Guarantee that o-rings refrain from getting a tight squeeze by removing the o-ring and using a hand-tight connection prior to brazing or welding the tailpiece (or threaded pipe) to the pipe ends.

Use a welding spacer when installing an o-ring to a valve end connections. Be sure to remove internal parts to avoid heat welding damage.

Stop 6000 PSI o-seal seepage to prevent materials to leak in or leak out

For tight sealing, o-ring and the seating surfaces should be inspected for foreign material or surface imperfections.

Stem leakages are detected by checking the sealing area of the stem. Prevent damage to stem seal edges by ensuring the grooved end of the seal always faces the valve seat.

Share

Posted by CPV Manufacturing

Since 1915 CPV has provided leadership in the development of leak proof valves and fittings. Our leading edge engineerin... Read more