Conveying Cycle Optimizer by piab moves more with less energy

Conveying Cycle Optimizer by piab moves more with less energy

September 6, 2022 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

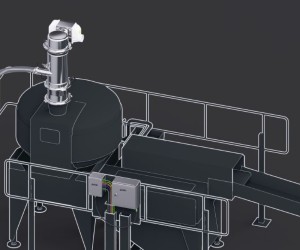

The piab CCO, available from Firing Industries

piab’s vacuum conveying solutions are available from Firing Industries Ltd. This includes the semi-automated piFLOW®p SMART Conveying Cycle Optimizer, or CCO, a recent addition to the manufacturer’s premium conveyor series. This device is designed to move more material at once with fewer operating skills needed and reduced energy costs.

The piab CCO focuses on the demands of continuous production, allowing pickup of materials through a pipe or feed nozzle from a bag dump station or barrel.

Only one parameter required

Users require fewer cycles to move product to packaging, sieving, milling, or dosing operations. The CCO optimizes the conveying process by maximizing the use of system capacity with every cycle. The dual-sensor solutions allows the device to use the whole batch volume in every cycle, and only one parameter needs to be set, that of the air-carrying valve. The conveyor itself adapts all other settings as necessary.

The top sensor measures the quantity in the conveyor and halts the filling cycle when it reaches the maximum level. It also stops material overfill by shutting down the conveying cycle before materials reach the filter, virtually eliminating filter breakage and therefore decreasing downtime and replacement expenses. The bottom sensor closes the bottom lid when the body is empty, causing immediate restart of the process.

The filter is cleaned by a shock of compressed air during discharge, which helps to extend filter lifespan. This system from Firing Industries can be set to perform one to five filter shocks, depending on the material, and an air channel blow-cleans the sensor heads by pulses of compressed air until the sensors are de-triggered. All settings are done at the electrical control unit and visualized through a user-friendly human-machine interface.

The CCO is nearly as easy to operate as a screw conveyor is. All that is needed is to set the carrying air, as the device automatically adjusts suction and discharge times to the material flow. This relieves the user from controlling three parameters and spending several cycles fine-tuning the process for better results.

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more