Continental’s belt conveyor pulleys reduce belt wear, prevent misalignment

Continental’s belt conveyor pulleys reduce belt wear, prevent misalignment

December 30, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

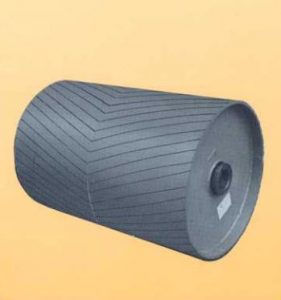

Belt conveyor pulleys come in three standard designs.

Since its founding in 1963, Continental Conveyor has served Canadian businesses as a leading manufacturer of equipment and systems that handle bulk materials. The company offers a broad lineup of conveyor equipment and components to meet virtually any industrial need – such as standard and custom belt conveyor pulleys. Continental has designed and fabricated these pulleys to suit every individual requirement a customer could possibly have. These units come in three standard categories.

Custom variations are available

In addition to the standard designs, customized pulleys are available. Continental can make modifications to its standard drum-style belt conveyor pulleys to suit specific customer requirements. The company also has the ability to engineer special self-cleaning pulleys for any application. For example, one customer received a custom-built pulley that had stainless steel construction and a fully open design. The Continental team has the skills, training, and experience to make a belt conveyor pulley to fit any relevant circumstance.

Continental Conveyor offers a standard selection of welded steel conveyor pulleys in a variety of designs. Options for belt conveyor pulleys include the following:

- Lagged wing pulleys – Perfect for applications in which a buildup of material between the conveyor belt and pulley is causing belt misalignment and excessive wear. Also suit cases that need higher tractive capacity between belt and pulley.

- Spiral drum pulleys – These units help reduce belt wear and misalignment, along with the potential for material buildup between the belt and pulley in applications in which self-cleaning wing pulleys are impractical. Each unit is formed by a pair of vertical steel flat bars helically wound around a drum.

- Spiral wing pulleys – Used for applications that need reduction in material buildup between the belt and pulley. These products have self-cleaning features that begin when rotation starts and material is discharged to both sides of the conveyor. Each of these pulleys is made by helically winding a pair of flat steel bars around the wing pulley; this design minimizes belt misalignment, reduces belt wear, and is available in either a flat or crown face in most standard sizes.

For more information, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more