Continental makes several different custom belt-conveyor pulleys for varying needs

Continental makes several different custom belt-conveyor pulleys for varying needs

September 22, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

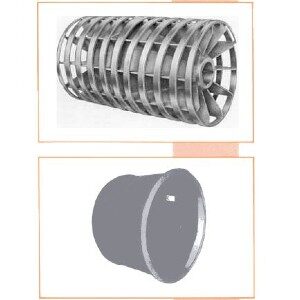

Belt-conveyor pulleys come in many forms.

For close to 60 years, Continental Conveyor Ltd. has supplied world-class industrial material-handling solutions. The broad portfolio includes such vital components as belt-conveyor pulleys. A key advantage of collaborating with the Continental team is its unmatched skill in designing and manufacturing custom belt-conveyor pulleys that meet virtual any customer need.

While these pulleys are available in several standard drum-style models, the company also offers customized modifications to accommodate unique applications.

Lagged, spiral, or special

One way that the company customizes its belt-conveyor pulleys is with lagging, which is primarily used in environments that require raising the tractive capacity in drive applications or for resisting abrasive conditions in other scenarios. Through a vulcanizing process, vulcanized rubber lagging with no cloth fabric is applied directly to the pulley face, which leaves a cloth impression on the finished rubber surface. Machined lagged pulleys are recommended for tasks that need exact tolerances.

Another option for custom belt-conveyor pulleys is herringbone rubber lagging, used to boost the tractive capacity of a pulley under wet or dirty conditions in which plain lagging is insufficient. The herringbone design stops buildup of foreign materials between the belt and pulley surface, reducing belt wear and minimizing misalignment. Continental can bond a quality rubber lagging directly to special traction pads fitted to the pulley rim by special retaining bars.

Some models of custom belt-conveyor pulleys:

- Lagged wing pulleys. Recommended for applications involving material buildup between the conveyor belt and pulley, leading to belt misalignment and wear.

- Spiral drum pulleys. A unique design that minimizes belt wear and misalignment. Rotation automatically begins a self-cleaning action, discharging foreign materials to the conveyor sides.

- Special drum-style pulleys. Special modifications are available to standard pulleys to suit individual requirements, like adding retaining rims to ensure alignment.

- Special self-cleaning pulleys. When pulleys come in contact with acidic baths, they can adopt a fully stainless steel construction or an entirely open design.

- Spiral wing pulleys. These are for conditions requiring reduction of material buildup between pulley and belt, while using the wing principle of the self-cleaning pulley.

To learn more, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more