Contact plating material options for electronic connectors: Part 5

Contact plating material options for electronic connectors: Part 5

February 1, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Harting Canada Inc

The family-owned HARTING Group is a global leader in connectivity solutions. HARTING invented the modular connector and... Read more

Subscribe

Free REDWIRE e-newsletter

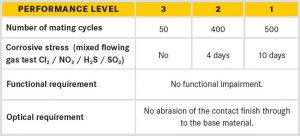

Performance levels 1-3 as per IEC 60 603-2

In this six-part article, the HARTING Technology Group discusses plug-in connectors and options available for contact plating. This part deals with selecting the right surface and comparing hard gold with hard-gold-flashed palladium nickel. Read Part 1, Part 2, Part 3, and Part 4.

Selection of the right surface

Since the majority of the functional disorder in connectors is caused by the contact elements, the most common defect mechanism of the connector’s contact surface is corrosion and wear of the layer. These degradation mechanisms have a big impact on the performance of the contact. Thus the proper selection of the contact finish requires an understanding of the characteristics of the different contact surfaces and of the engineering requirements. To make it simple for customers to define the right connector for their application different performance levels are defined in standards like IEC 60 603-2. Hard gold, as well as hard-gold-flashed palladium-nickel (80/20), fulfills these requirements. This provides advantages for the customer as well as for the manufacturer. The customers do not have to define technical characteristics like maximum contact resistance, number of mating cycles, plating, or aging procedure individually by themselves. They can just choose a defined performance level, and the connector manufacturer is responsible to fulfill the required specification. On the other hand, the standardization gives the manufacturer some freedom to achieve these performance levels by using new technologies – for example, in the field of stamping or plating, or by using new materials, base materials as well as surface coatings, which are under continuous development and which have an important impact on the performance of the connector.

Comparison of hard gold and hard gold flashed palladium nickel (80/20)

The most technical concern against hard-gold-flashed palladium nickel (80/20) is about the fretting corrosion behavior. Additional to the release test (according to IEC 60 603-2), the test specimens were subjected to a fretting test based on Telcordia GR-1217, to verify all the existing theoretical comparison between gold and palladium. Therefore, HARTING did a specific comparison of identical DIN 41612 connectors type C with these two contact surfaces. The Corporate Technology Services (CTS) of HARTING AG & Co. KG, which tests the products to ensure the quality as an independent service provider for the entire HARTING Technology Group, performed all the tests. The accreditation according to DIN EN ISO/IEC 17025 ensures the independence of the laboratory and the high quality of the results.

Test specimen

The surface coatings of the two samples have the following layout:

- Sample type 1: DIN 41612 connectors type C

— contact surface: 2 μm Ni + 1.85 μm AuCo - Sample type 2: DIN 41612 connectors type C (performance level 1)

— contact surface: 2 μm Ni + 0.4 μm PdNi (80/20) and 0.05 μm AuCo

For the interpretation of the results, it should be taken into account that the layer thickness of the sample type 1 with hard gold is four times thicker (AuCo: 1.85 μm) than the layer thickness of hard-gold-flashed palladium nickel (80/20) of sample type 2 (PdNi: 0.4 μm).

Coming up in Part 6: Test arrangement and summary

For more information, contact HARTING.

Share

Posted by Harting Canada Inc

The family-owned HARTING Group is a global leader in connectivity solutions. HARTING invented the modular connector and... Read more