Coatings for broach tools offer extended tool life

Coatings for broach tools offer extended tool life

June 22, 2016 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more

Subscribe

Free REDWIRE e-newsletter

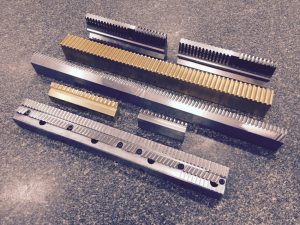

The Ohio Broach & Machine Company provides a range of services to keep broach tools working properly. They include sharpening, emergency repairs, reconditioning, deburring, welding, straightening and alterations. The company can also provide a number of coatings that improve tool performance and lifespan.

Broach tool coatings

The coatings available include titanium nitride, titanium carbonitride and titanium aluminum nitride. These thin coatings have little impact on dimensions, so they are ideal for coating parts with tight tolerances, such as broach tools. Tools with these coatings typically last between three to 10 times longer.

TiN

Titanium nitride (TiN), also referred to as tinite, is a ceramic material that offers extreme hardness. It is often used for hardening and protecting cutting and sliding surfaces. The material also provides edge retention and corrosion resistance when used as a coating for machine tooling. In addition, TiN is used in medical devices ranging from scalpel blades to hip replacement implants, as it is non-toxic and meets FDA guidelines. TiN coating is also sometimes used for decorative applications such as automotive trim and costume jewelry due to its metallic gold colour.

TiCN

Titanium carbonitride (TiCN) is a thin film coating that offers more hardness and lower friction of coefficient when compared to TiN. It is typically used to enhance wear resistance. However, TiCN has a lower temperature limit and does not outperform TiN in every application. This coating can eliminate galling, fretting and microwelding.

TiAlN

Titanium aluminum nitride (TiAlN) is a group of coatings that consist of aluminum, titanium and nitrogen. When compared to TiN coatings, they offer increased hardness, oxidation resistance and age hardening.

For more information on its tool sharpening, reconditioning and repair services, visit the Ohio Broach website.

Share

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more