Bergen Cable on the key basics of wire rope stretch

Bergen Cable on the key basics of wire rope stretch

January 29, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more

Subscribe

Free REDWIRE e-newsletter

Bergen Cable identifies two basic factors that affect wire rope stretch: structural stretch and elastic stretch.

One reason to trust Bergen Cable is its breadth of expertise. The company’s website is a great source of useful information. The Cable 101 page contains the basics – including a section on wire rope stretch. Stretch is a major trait to consider when selecting wire rope for any work application or inspecting the wire rope that employees are using. In fact, most occupational health and safety standards advise users to check the stretch of wire rope regularly when under load.

Elastic and structural stretch

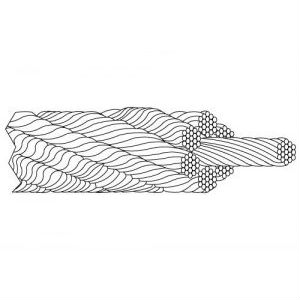

Although the term “wire rope” is often used as a synonym for “cable”, it refers to rope with diameters exceeding 3/8 of an inch. The Bergen Cable website identifies two basic factors that affect wire rope stretch: structural stretch and elastic stretch. Structural stretch is caused by a combination of lengthening of the rope lay, compression of the core, and adjustment of the wires and strands to the load that the rope is holding. Elastic stretch is caused merely by elongation of the wires.

The core size, length of the lays, and the wire rope’s construction all affect the structural stretch, as do the loads and the amount of bending that users impose on the wire rope. To estimate the quantitative value of a wire rope’s structural stretch, multiply the length of the rope by 0.005 when it is under a medium-weighted load. For a heavy load, multiply the length by 0.01 instead, and for a light load, use the factor 0.0025.

Elastic wire rope stretch is proportional to load weight and rope length when it holds a load under the rope’s elastic limit. The elastic limit of galvanized wire rope is typically about 50 per cent of its breaking strength, or about three-fifths in the case of stainless steel rope. Elastic stretch is also inversely proportional to the rope’s metallic area and modulus of elasticity. To calculate elastic stretch in feet, multiply the load weight in pounds by the rope length in feet, then divide the answer by the metallic area in square inches multiplied by the modulus.

For more information, contact Bergen Cable.

Share

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more