Bergen Cable makes it easy to get the perfect assembly

Bergen Cable makes it easy to get the perfect assembly

January 26, 2016 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more

Subscribe

Free REDWIRE e-newsletter

Bergen Cable Technology makes it easy for customers to get the cable assembly they are looking for. One way the company accomplishes this is through its website, which includes plenty of helpful information on the fundamentals of cable assemblies, including cable construction, materials, tolerances, and how to select the right cable for a particular application. Once customers have brushed up their knowledge of assemblies and have their requirements in mind, the website also includes a cable assembly request form.

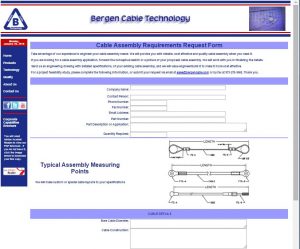

Cable assembly requirements request form

The request form allows customers to specify their requirements for a cable assembly, and the company then works with them to finalize the details and engineer a solution. The request form provides space for customers to include details on the cable requirements, such as bare cable diameter, cable construction, cable material and coating. The form also provides a diagram that identifies typical assembly measuring points on various types of assemblies. Several types of cable constructions are available with varying numbers of strands and wires, ranging from 1×7 (one strand and seven wires) up to 7×19 (seven strands and 19 wires). The materials typically used include stainless steels 302, 304, 305, 316 and 321, as well as galvanized carbon steel.

Another section of the request form focuses on the assembly requirements, including required proof-load and breaking strength. Bergen Cable Technology advises customers that a reasonable safety factor should be applied to the working load in order to assure long life. In addition, when determining the working load, both the direct stress and the shock in bending loads have to be considered. While a safety factor of 5:1 is standard industry practice, higher safety factors are used in certain critical applications like aircraft control assemblies.

The last section of the form provides space to specify the fitting types and fitting materials required. The company offers a variety of fittings, typically supplied in stainless steel or zinc plated carbon steel. Some of the different types of fittings available include eye, plug and threaded end.

More information

Bergen Cable Technology has been serving the industry for more than 60 years. The company’s manufacturing process offers flexibility, which allows it to make assemblies for many different applications, from aerospace and military to medical and furniture applications.

For more information, visit the company’s website.

Share

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more