Belt conveyor idlers by Continental work with many important parts

Belt conveyor idlers by Continental work with many important parts

October 12, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

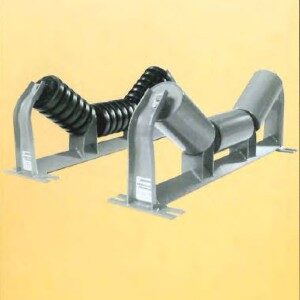

Continental makes belt conveyor idlers, among other material-handling components.

Continental Conveyor Ltd. manufactures not just material-handling systems, but also their components – like two types of belt conveyor idlers. Series 30000 idlers are designed for continuous operation, in addition to high capacities and heavy, abrasive materials in which the belt width limits the lump size. These components are made with many parts that have their own unique functions, to keep belt conveyor idlers working at the height of their ability.

A broad range of variations

Available in belt widths of up to five feet, the belt conveyor idlers in Series 30000 comes in a broad range of variations, such as flat-belt-carrying rubber cushion, training idlers, picking roll, and variable troughing idlers. Return belt idlers are available in rubber-tread, beater, and training models.

The following parts go into these Continental units:

- heavy-duty, deep-groove ball bearings with long-lasting seals;

- heavy-gauge steel rolls, carefully checked for smooth running before installation;

- non-clogging centre brackets, die-formed to close tolerances;

- non-jamming end bracket for rigid support of heavy loads;

- self-cleaning, inverted-angle cross member that stays clean; and

- sturdy oversized shafts for maximum rigidity.

All of the rolls are equipped with precision ball bearings. A separate cartridge-type contact and labyrinth grease seal offers triple bearing protection with neoprene contact members and grease-filled clearances. The counter-bored outer shell and stamped-end disc are swaged to perfect concentricity and welded constantly to form an airtight concentric unit. The stamping cavity is filled with grease before assembly, and its large diameter allows easy movement of grease to the bearings. The efficient grease-in, cartridge seal, and large reservoir of grease result in a longer lifespan.

Measuring two centimetres in diameter, the through-shaft of each belt conveyor idler is machined at both ends. The bearings are factory-adjusted by press-fitting the cartridge seal and beating into the roll-end disc. The inverted-angle base has slotted foot straps that allow easy, fast mounting and alignment. The formed steel brackets are jig-welded to the base, to ensure roll alignment. Ribbed-end brackets are contoured to offer a large clearance, so that spilled material does not stall the rolls.

For more information, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more