Turnbuckles

At Ken Forging Inc., we manufacture forged metal fasteners such as turnbuckles. All our products are guaranteed to exceed your expectations. With 100% traceability and lot control for quality assurance, our customers receive the highest caliber products in the fastener industry at competitive prices. Ken Forging’s substantial inventory and same-day or next-day shipping ensures that our distributor customers receive our turnbuckles in record times. As a family-run business founded in 1970, our products remain proudly forged in our Ohio plant, but no matter where your business is, we always put your needs first.

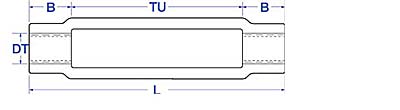

Turnbuckle Product Lines

We manufacture turnbuckle bodies, assemblies and fittings from stainless steels (3316 series), carbon steels (grades C1018 through C1045, including C1030 and C1035) and galvanized steels (4140 and F11 and F22). Assemblies are available as jaw-and-jaw, eye-and-eye, stub-and-stub or jaw-and-eye. Note that jaw-and-eye turnbuckle fittings are only available in carbon steel and galvanized steel. Turnbuckle fittings are available as eye, jaw and stub.

Turnbuckle Industrial Applications

Ken Forging Inc. has been manufacturing a variety of high-quality turnbuckles for distributors for over forty years. We have provided many clients in the tooling industry with forged set-up equipment, and have also worked extensively in the forged harware industry, providing clients with a wide range of structural components.

Turnbuckle Manufacturing Process and Customization Options

Our 130 dedicated employees working in our 250,000 square foot plant have the experience, expertise and equipment to provide you with top-quality turnbuckles. We’re also pleased to be one-stop shop for all your fastener needs, and we offer numerous in-house customization options. Finish options include plain (self colored), hot dip or electro galvanized (zinc), and electro-polished, and threading capabilities include UNC, UNF, Metric and ACME. We can also provide custom plating and special heat-treat processes.

Share