A & M Heat Treating Ltd.

1815 Drew Rd, Mississauga, Ontario, L5S1J5 Canada View map www.amheattreat.comT.D. Vanadium Carbide Ceramic Coatings

We provide the best T.D. vanadium carbide coating to lengthen the lifespan, lower the requirements for lubrication and reduce the maintenance needed for dies and other heavy duty industrial parts. Our one-of-a-kind process uses a fused salt bath at up to 1900 degrees Fahrenheit. The result is components that are much less susceptible to seizer, wear, corrosion and galling—saving you money and downtime. We are able to process your parts quickly and we offer affordable rates because our equipment has large capacities. Our processes will help improve the productivity of your parts and make them last.

Vanadium carbide

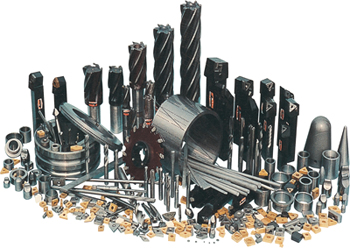

Our superior thermal diffusion process creates a V.C. layer between 0.001-0.008 inch thick. The layer has a hardness ranging from 3200 to 3800 HV, and it will retain that harness even at 1000 degrees Fahrenheit. Our thermal diffusion treated parts show virtually no wear when compared to hardened and tempered steel in wear resistance tests. It is the best coating option for parts such as core pins, cold forging dies, blank dies, mandrels, form punches and blocks.

We also provide other surface engineering services including gas nitriding, PlasmaNit, OxyCoat, FerrNit, hardening facilities and metallurgical laboratory services.

Vanadium carbide coating process

We are an accredited Arvin TD Center. Our process involves immersing the component in a molten salt bath at a temperature between 1600-1900 degrees Fahrenheit. The exact temperature depends on the type of metal being treated. Vanadium atoms in the salt bath combine with carbon atoms in the component’s substrate and create a strong V.C. layer. The layer continues to expand as it’s left in the salt bath and more carbon and vanadium atoms combine. The treatment continues for 1 to 8 hours.

Applications for TD treated parts

Parts that have been treated with our T.D. process are in use in a wide variety of applications including roll forming, die casting, deep drawing, extrusion, hydroforming, bonding, piercing and shearing.

TD Vanadium carbide Expertise

We have been in this business for over 20 years. Our consistent, high quality work is the secret to our success. We always take the utmost care with our work because our customers trust us with their most valuable parts. We are a member of The Society of Manufacturing Engineers (SME), the Heat Treating Society, and The Metal Treating Institute (MTI).

Share