Potting Compounds

Master Bond Inc. formulates a broad variety of epoxy, silicone, polyurethane and UV curable potting compounds. Our products offer excellent dielectric properties, mechanical strength, high/low temperature serviceability, moisture/chemical resistance. They are available for purchase in different grades depending on your application requirements. Our compounds are completely free of solvents and are employed to protect sensors, transformers, switches, relays, capacitors, motors, control modules against harsh environmental conditions including humidity, vibration, impact, shock, thermal cycling, high intensity sunlight, heat aging.

Master Bond has over 40 years experience in helping electronics, automotive, aerospace, electrical, telecommunication, appliance manufacturing companies solve problems. We take special pride in providing one on one technical service and recommending potting compounds that give our customers a competitive edge. Our high quality systems are known for their dependability, reliability, durability in meeting demanding specifications. We also collaborate with our suppliers to develop the most technologically advanced products. Master Bond’s team of research chemists is actively investigating compounding new improved ingredients such as nanosilica for enhanced performance.

Performance Properties for Potting Compounds

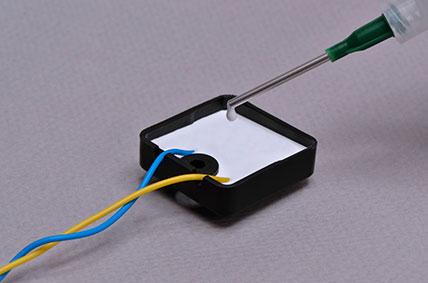

Our potting compounds are room temperature, heat and UV curable systems. Low/medium viscosity compositions have good flow properties and after dispensing into a potting case are engineered to prevent air entrapment. Master Bond rigid/flexible eco-friendly potting compound formulations are ROHS compliant. They can be applied manually or automatically for high volume production. Standard colors range from black, red, green to blue, silver, white. We also have optically clear systems. Our products feature consistent, reproducible performance and improved aesthetics.

Select Master Bond potting compounds have the following industrial certifications:

- USP Class VI for biocompatibility

- NASA low outgassing

- FAR 25.853(a) for flame retardancy

- FDA CFR 175.105 and CFR 175.300 for food grade

- UL94V-0 and UL94V-1 for flame retardancy

- ISO 10993-5 for cytotoxicity

- IEC 61249-2-21 halogen free

Additionally, Master Bond potting systems have successfully passed 85°C/85% RH testing for damp heat storage per requirements within the Telecordia GR-1221 specification.

Two Part Potting Compounds

Thermally conductive/electrically insulative Master Bond EP30FLAO epoxy potting compound has excellent toughness and a low thermal expansion coefficient. This compound has a low mixed viscosity of 4,000-7,000 cps and is serviceable from 4K to +250°F. Master Bond EP21LV has a convenient one to one mix ratio by weight or volume. Ideal for potting, this system exhibits durability, chemical resistance and meets FDA requirements for indirect food contact. Our EP21FRNS-2 potting compound is noted for being flame retardant per the UL94V-0 specification. It has a non-halogen filler, good flow and guards well against fuels and lubricants. Thermally conductive EP29LPSPAO can withstand thermal shock. This two component composition has a long pot life, low exotherm and can be employed for large volume potting.

Silicone Potting Compounds

Our silicone potting compounds have exemplary temperature resistance and elasticity/flexibility. Two component addition curing MasterSil 151 potting compound is a low shrinkage materials with outstanding optical clarity. It is capable of withstanding thermal cycling and can cure in thicknesses beyond 1 inch. Master Bond MasterSil 151AO has superior thermal dissipation properties and can be used up to +400°F. It will not outgas while curing and is highly resistant to water. Vacuum compatible MasterSil 971-LO fully complies with NASA low outgassing requirements. Our easy to mix product has a one to one mix ratio and is a first class electrical insulator. Its working life is 3-4 hours for a 100 gram batch.

Master Bond UV curable potting compounds require no mixing and cure rapidly upon exposure to a UV light source at a wavelength of 320-365 nm. Master Bond UV18S has superb toughness and robust chemical resistance. This product has outstanding light transmission characteristics, exceptionally low shrinkage and Shore D hardness of 55-60. Our UV15X-2 system can cure in sections up to ¼ inch. Its dimensional stability and ability to withstand wear is noteworthy. Newly introduced UV15-7NV has high bond strength, durability, optical clarity and is serviceable from -80°F to +300°F. USP Class VI approved Master Bond UV 15X6-Med2 has high flexibility and is used in medical device manufacturing. It is an ideal thermal/electrical insulator and provides protection against mechanical shocks.

For additional information please visit our website at www.masterbond.com.

Share