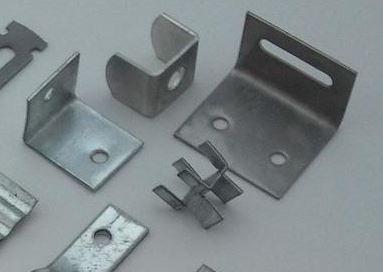

Multi-Slide Stampings

As an experienced custom manufacturer, Arcfil can produce multi-slide stampings to suit any need. Our company has been in business since 1979 and we regularly serve a wide variety of markets. To ensure our solutions satisfy clients’ requirements, we carefully listen to their needs and work with them throughout the process. We also continually reinvest in the latest and most efficient machinery. This equipment allows us to automate the production of forms and ensure high accuracy. Our goal is to ensure that every unit we ship meets the most exacting standards.

Multi-slide stamping capabilities

We use multi-slides machines with 29-1/2 inch stroke that can form wire up to 5/16 inch and flat strip up to 3/16 inch thick. We also have metal stamping capability up to 100 tonnes, and a variety of four slidesmachines, CNC wire forming machines, and wire straightening and cutting machines.

Extensive experience

Over our decades in the industry, we have developed strong expertise. For instance, we have experience making a variety of spring clips using our four-slide and multi-slide machinery. We can provide full-service spring clip development, from the initial concept to full scale production. During the design process we can work with customers to find the most cost-effective solutions.

Some of the industries that we have created spring clips for include medical, aerospace, automotive, appliances, construction, and telecommunications.

Materials and coatings

Arcfil can work with a variety of materials including galvanized low carbon steel, spring or high carbon steel, spring or high carbon steel, stainless steel, and non-ferrous metals such as brass, aluminum, beryllium copper, Elgiloy, Hastelloy, and Titanium. A range of options are also available for coating and plating services. These coatings will provide a better finish and improved durability. They include powder coating, e-coating, dip-and-spin, or electro-plating with chrome, black, black oxide, brass, bronze, copper, or zinc.

Share