Galvanized Bolts

Ken Forging Inc. offer a range of galvanized bolts. We are a full service manufacturer and we forge a variety of industrial hardware and fasteners. Our line of eyebolts includes many options for size, design, material and more. These standard items are available with same-day shipping, or we can custom forge a bolt to meet your needs. The materials we use for our bolts include a variety of alloy steel, stainless steel, and carbon steel. We have been serving the industry and putting our customers first for more than 45 years.

Galvanized bolts

We can perform both hot dip galvanizing and electro galvanizing. Hot dipping provides much thicker zinc deposits than electro galvanizing, and as a result, offers longer lasting corrosion resistance. The benefits of electro galvanizing include better aesthetics, less distortion of threading or precision parts, and similar performance achievable with a thinner coating.

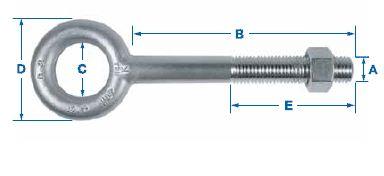

Here are some details on the plain pattern galvanized eyebolts we offer in carbon steel.

|

Stock No. |

|

A Shank Dia. & Thread UNC-2A* |

B Shank Length |

C Eye I.D. |

D Eye O.D. |

Weight |

|

K2003-HDG |

|

3/8-16 |

1 1/4 |

1 |

1 21/32 |

0.15 |

|

K2005-HDG |

|

1/2-13 |

1 1/2 |

1 3/16 |

2 1/16 |

0.30 |

|

K2007-HDG |

|

5/8-11 |

1 3/4 |

1 3/8 |

2 1/2 |

0.61 |

|

K2008-HDG |

|

3/4-10 |

2 |

1 1/2 |

2 13/16 |

0.98 |

|

K2009-HDG |

|

7/8-9 |

2 1/4 |

1 11/16 |

3 1/4 |

1.53 |

|

K2010-HDG |

|

1-8 |

2 1/2 |

1 13/16 |

3 9/16 |

2.06 |

|

K2011-HDG |

|

1 1/8-7 |

2 3/4 |

2 |

4 |

2.96 |

|

K2012-HDG |

|

1 1/4-7 |

3 |

2 3/16 |

4 7/16 |

4.11 |

|

K2014-HDG |

|

1 1/2-6 |

3 1/2 |

2 1/2 |

5 3/16 |

6.73 |

|

K2015-HDG |

|

1 3/4-5 |

3-3/4 |

2-7/8 |

6-1/16 |

11.00 |

|

K2016-HDG |

|

2-4 1/2 |

4 |

3-1/4 |

6-7/8 |

16.25 |

|

K2017-HDG |

|

2 1/2-4 |

5 |

4 |

8 9/16 |

28.00 |

|

*Before galvanizing. Galvanized bolt expertise Our company was founded back in 1970, and since then we have grown from a one-man operation to a leading manufacturer with 130 employees. Over the past 45 years we have continually expanded our capabilities and offering so we can provide our customers with the best forgings for their applications. Galvanized bolt manufacturing process We have a cutting-edge facility that spans 250,000 square feet. Our equipment and dedicated professionals allow us to offer products of to quality with rapid turnaround. To ensure all our products are of the high caliber our customers have come to expect, we utilize stringent quality control including 100 per cent traceability, lot control, load tests, and magnetic particle inspections. |

||||||

Share