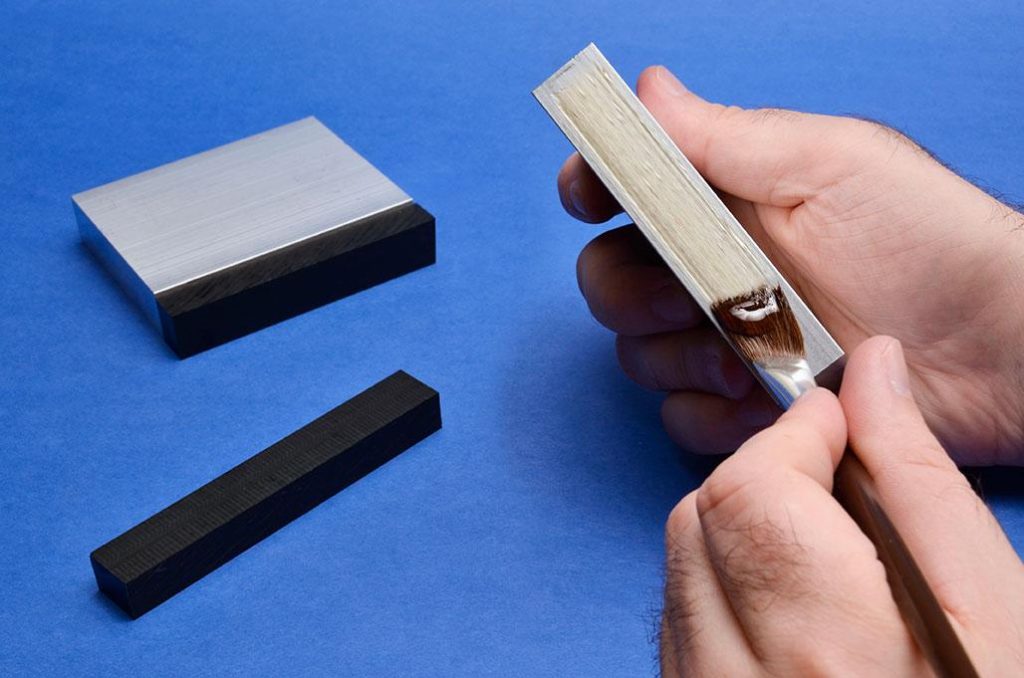

Epoxy Adhesives

Master Bond Inc. is a leading manufacturer of one and two component epoxy adhesives for structural bonding applications. Our products are employed as an alternative to mechanical fastening or thermal joining. Master Bond epoxy systems offer superior load bearing capacity and even stress distribution over wide surface areas to provide solutions for challenging requirements. Our high, medium, and low viscosity products have good wetting properties and excellent adhesion to properly prepared similar/dissimilar substrates including metals, ceramics, rubbers, plastics. They exhibit strength retention after prolonged aging, moisture and humidity resistance, protection against erosion/corrosion and thermal stability. These versatile systems can be conveniently dispensed manually or automatically to speed processing and lower production costs.

One Component Epoxies

Master Bond single component epoxy adhesives require no mixing and polymerize with heat or UV light. Our solvent free products have a long shelf life at ambient temperatures. We have also developed dual cure compositions that feature UV cure and a secondary curing mechanism for "shadowed out" areas at moderate temperatures. UV cure adhesives will cure on demand to allow precise alignment of parts. Master Bond grades are available that have outstanding optical clarity, superb physical strength, withstand exposure to acids, bases, fuels, solvents, and have a high Tg.

Two Component Epoxies

Technologically advanced Master Bond two component epoxy adhesives cure at room or elevated temperatures and have unmatched performance capabilities. A broad range of diverse systems provide innovative cost effective solutions for optical, electronic, electrical, medical device, oil/gas equipment, appliance, and aerospace manufacturing companies. Our formulations are tailor made to meet exact specifications, speed up assembly, and improve efficiency. These nonconductive/conductive polymeric products contain different resins, catalysts, fillers, pigments, modifiers, flexibilizers, tougheners, etc. that are compounded to satisfy the exact viscosity, hardness, cure speeds, and other performance properties desired by the end user.

Master Bond compounds are engineered to ensure the adhesive/cohesive strength of mated joints that will perform effectively under adverse environmental conditions. Our job proven two component adhesives will not crack, delaminate, blister, chalk, shrink, change color assuring structural integrity and long term durability of assembled equipment/components. Widely used systems have exceeded customer expectations to withstand stresses from tension, shear, impact, peel, cleavage, fatigue. Select products have superior dielectric strength, resist abrasion, thermal cycling, vibration/shock/sterilization, cure rapidly at room or low temperatures and are cryogenically serviceable.

Our epoxy adhesive products are ROHS compliant and numerous two component systems are available for purchase in dual component packaging or in premixed frozen syringes. Additionally Master Bond can modify existing epoxy compounds or custom formulate new systems to meet unique customer requirements. We have also supplied replacements for competitors discontinued products.

Certifications of Compliance

It is import to note that many of our epoxy adhesives have successfully passed 85°C/85%RH testing based on the requirements within the Telcordia GR-1221 test specifications for damp heat storage. Specific Master Bond grades have been approved for the following industrial certifications:

- USP Class VI for biocompatibility

- ISO10993-5 cytotoxicity

- FAR 25.853 for flame retardancy

- FDA CFR 175.300 and FDA CFR 175.105 for food

- UL 94V-0 for flame retardancy

- IEC 61249-2-21 for halogen free

Some of our most popular epoxy adhesives are:

EP17HT-LO: This unique one component heat curing epoxy adhesive exhibits serviceability up to 650°F, has a Tg of 225°C, is NASA low outgassing approved and is exceptionally chemical resistant.

EP30-4: Optically clear two component system is fast setting in thin sections at room temperature.

EP21AR: Low viscosity two part epoxy has a convenient 2 to 1 mix ratio, cures at ambient temperatures and has outstanding chemical resistance to acids (most noteworthy to sulfuric and hydrochloric acids).

EP42HT-2LTE: This compound features an ultra lowcoefficient of thermal expansion, has high compressive strength, withstands 1,000 hours at 85°C/85%RH and is cryogenically serviceable.

Supreme 10AOHT: One part toughened epoxy adhesive offers superior thermal conductivity and excellent peel/shear strength properties for service from 4K to +400°F.

For more information, visit the Master Bond Inc. website.

Share