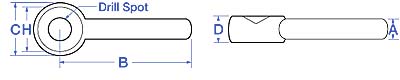

Ends – Rod

Since 1970, Ken Forging Inc. has been committed to customer satisfaction. We design and manufacture rod ends, turnbuckles, eye nuts and other drop-forged industrial hardware, all guaranteed to exceed your expectations. We are proud to offer some of the highest quality products in the fastener industry, as well as competitive prices, and 100% traceability and lot control. Our well-stocked warehouse allows us to provide same-day or next-day shipping. As a one-stop shop for all your fastener needs, we can provide many in-house customization options. We are proud to manufacture all products in our Jefferson, Ohio facilities, but no matter where you’re located, we would be pleased to help make running your business as easy as possible.

Rod Ends Product Line

We manufacture rod ends from stainless steels (304 and 316 series), carbon steels (C1030, C1035, C1045) and drop forged alloy steel (4140). Some models are heat treated to ASTM A193-B7, and all can be modified to suit your exact specifications for an additional cost. Rod ends are available in blank, machined, machined & black oxided, machined & black oxided fine thread, and machined fine thread models.

Rod Ends Industrial Applications

We provide many clients in the tooling industry with forged set-up equipment, and have also worked extensively with the forged hardware industry, providing clients with a wide range of structural components.

Rod Ends Manufacturing Process and Customization Options

With 130 dedicated employees working in our 250,000 square foot plant, we have the expertise and equipment to provide you with top-quality rod ends. These products can also be customized. Finish options include plain (self colored), hot dip or electro galvanized (zinc), and electro-polished, and threading capabilities include UNC, UNF, Metric and ACME. We can also provide custom plating and special heat-treat processes.

Share