Electrically Conductive Adhesives

Master Bond Inc. offers a wide variety of electrically conductive adhesives, sealants and coatings to meet precise performance requirements. These systems are formulated with graphite, nickel, silver coated nickel and silver fillers to deliver low volume resistivity and also impart superior EMI/RFI shielding characteristics. Each filler features its own distinct advantages. For example, graphite conductive adhesives are ideal applications that require a non-magnetic adhesive with high lubricity. Nickel and silver coated nickel is a cost effective options for many applications.

Performance properties of electrically conductive adhesives, sealants and coatings

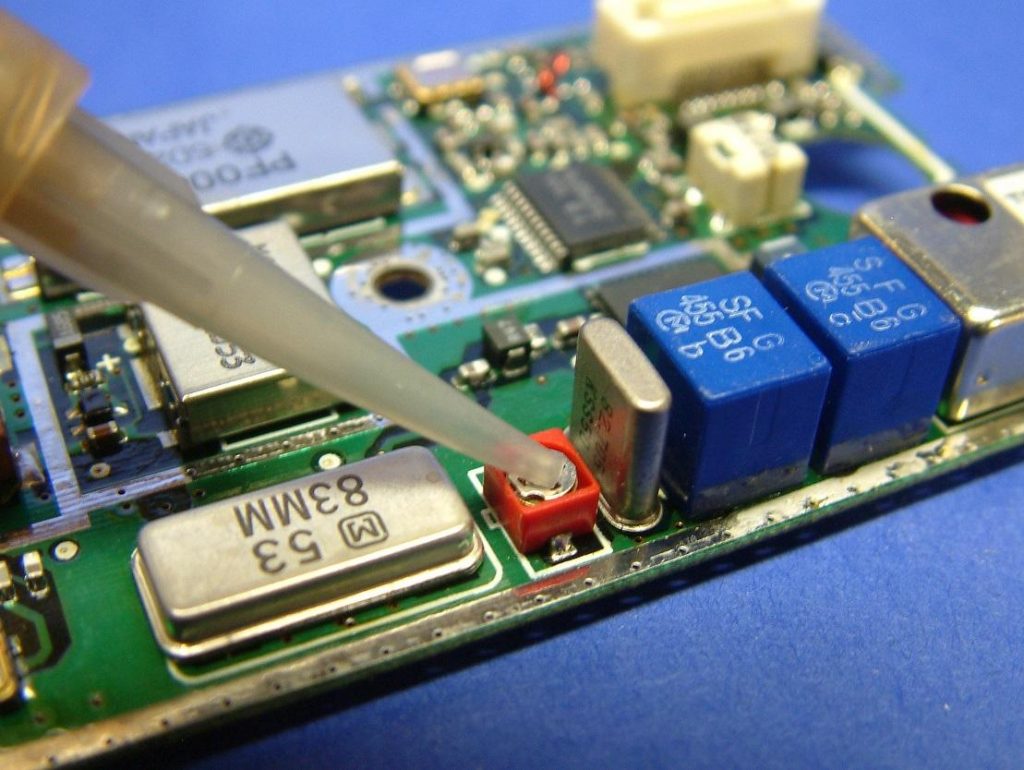

Master Bond electrically conductive epoxies and silicones provide high reliability and excellent adhesion to similar and dissimilar substrates. In fact, our systems are often used as an alternative to solder. These adhesives are easy to handle, can be formulated with a range of viscosities and offer convenient room temperature and elevated cure schedules. Our products are serviceable at high and low temperatures and can withstand rigorous thermal cycling. Specific grades meet NASA low outgassing and USP Class VI specifications.

Master Bond products featuring electrical conductivity

Our electrically conductive products are often used in the electronic, automotive, electrical, medical, aerospace and electro-optic industries. A selection our most popular products include:

- EP21TDCSFL is a two component, silver conductive epoxy with very low exotherm. It can be easily applied with very little sagging on vertical surfaces. This system is able to withstand cryogenic temperatures down to 4K, it is highly flexible and resists rigorous thermal cycling.

- MasterSil 155 is a graphite filled, two part silicone has a smooth paste consistency and cures to a black rubber offering superior protection against vibration, impact and shock. It is well suited for dissipating static electricity and for EMI/RFI shielding.

- EP76M is a nickel filled polymer system featuring first rate electrical conductivity and high strength bonds. It has impressive durability, thermal shock and chemical resistance.

- EP79 is a silver coated nickel filled epoxy that provides a more cost effective alternative to silver filled systems but retains low volume resistivity. This compound offers high peel strength and superb toughness. Suitable for cryogenic conditions, it has a service temperature range of 4K to +275°F.

For more information, visit the Master Bond Inc. website.

Share