Electrical/Electronics Epoxies

Master Bond Inc. is a leading manufacturer of epoxy adhesives, sealants, coatings, potting and encapsulation compounds. Master Bond offers custom formulations to meet the rigorous needs of the electronics industry, specializing in conformal coatings, glob tops, flip chip underfills, die attach, surface mount and lid sealing.

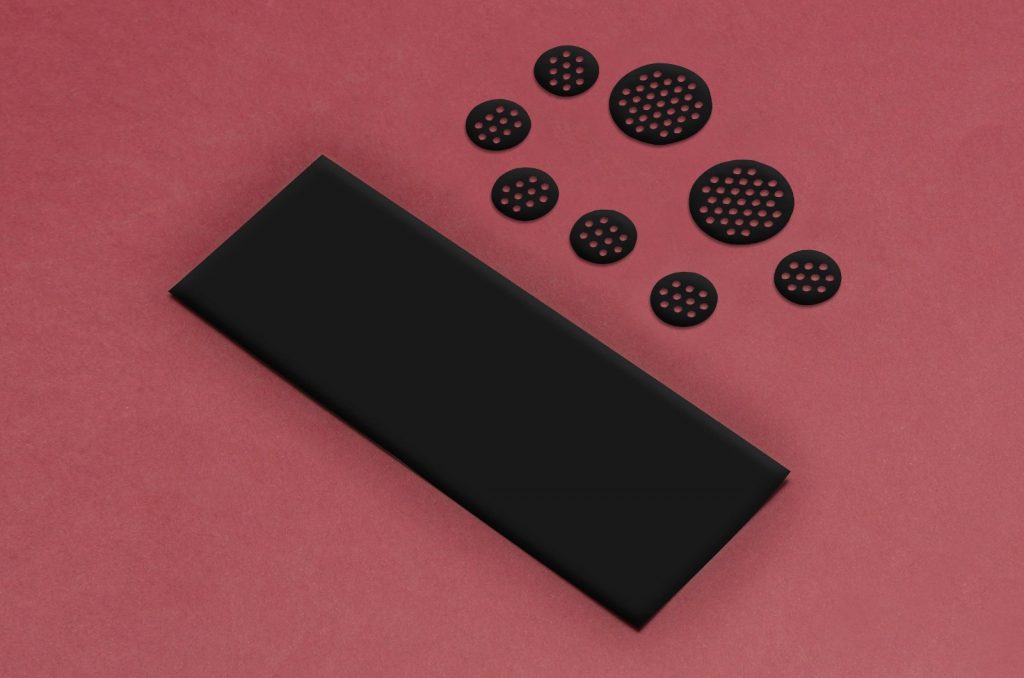

Epoxies for electrical and electronic assembly such as microwave and RF, printed circuit boards and semiconductor packaging, are designed for ease of use and reliability. The extensive array of epoxy formulations offers engineers a variety of formats and curing characteristics designed to meet different manufacturing needs. Epoxies are available as liquids, pastes, films, and solids.

Performance properties of Master Bond electrical and electronics epoxy adhesives

Formulations can also be modified to achieve a vast assortment of performance characteristics. Among the properties that can be controlled through each specific formulation are thermal conductivity, electrical conductivity, cohesive strength, hardness, durability, flexibility, viscosity and the ability to withstand high and low temperatures, chemicals, moisture, shock and vibration.

Because of their wide range of physical properties, epoxies are often engineered specifically to perform additional functions, such as dissipating heat, providing an electrically conductive pathway between substrates, or relieving stress between substrates. The outstanding performance and versatility of epoxy compounds has proven to be a tremendous asset to the electronics industry.

Master Bond epoxies for the assembly of electronics and electrical devices

- EP3HT is a one component adhesive/sealant that withstands thermal cycling and many harsh chemicals. After curing, it readily obtains a tensile lap shear strength in excess of 2,200 psi and has also been successfully tested for 1,000 hours at 85°C/85 RH.

- EP21TCHT-1 is a two component, thermally conductive, heat resistant epoxy compound formulated to cure at ambient temperatures. This NASA low outgassing approved epoxy is highly recommended for use in vacuum environments.

- UV10TK40 is a one part, high viscosity UV system that offers excellent dimensional stability. Optically clear, it is effectively used for high volume production applications where fast fixture times and rapid curing are critical.

- LED401 is a unique single component compound that cures rapidly upon exposure to 405 nm light.This formulation has a good flow, high bond strength and superior electrical insulation properties.

- MasterSil 705TC is a thermally conductive, electrically isolating silicone for bonding, sealing and coating applications. It is well suited for applications that require flexibility and high temperature resistance where a degree of reworkability is desired.

- FLM36 is a film adhesive featuring excellent thermal conductivity and electrical insulation properties. FLM36 retains high physical strength properties at temperatures up to 500°F, while combining enhanced thermal and mechanical shock resistance and thermal cycling capabilities.

Share