Conformal Adhesive Coatings

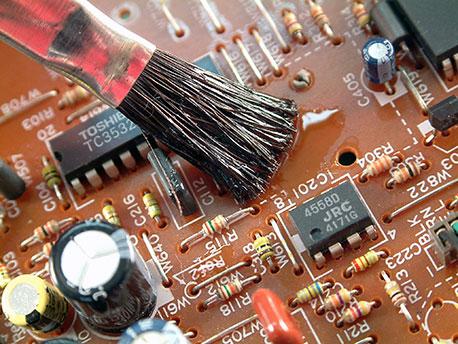

Master Bond Inc. conformal coatings consist of epoxy, silicone, polyurethane and UV curable systems. These low viscosity, solvent free Master Bond compounds can be applied by dipping, spraying, brushing, robotic coating to protect and guard against hostile environmental conditions. This includes moisture, dust, dirt, chemical attack, salt sprays, fungus, thermal cycling, vibration/impact. Our products have superior electrical insulation properties, minimize stress and enhance product reliability. These ecologically friendly formulations are highly durable and are engineered to extend device longevity.

Master Bond conformal coatings are rigid/flexible, light weight, have good wetting characteristics and cost effectiveness. We mix these products using only the finest ingredients to protect PCBs against abrasion, erosion/corrosion, airborne contaminants and dendrite growth. Select room temperature, heat, moisture, UV cure systems are optically clear, cryogenically serviceable, withstand harsh chemical/solvents, pass NASA low outgassing specifications. Additionally, Master Bond has developed compounds that have high temperature resistance, fully cure in only seconds for high volume production and are repairable. We also can modify existing formulations to best meet end use requirements.

Our team of technical representatives will work with you to help find solutions for your exact needs. Master Bond has over 40 years in formulating products for demanding requirements. Our conformal coatings are employed in automotive underhood applications, mobile devices, appliances, defense/aerospace systems and subsystems. We take special pride in supplying high quality products that enable our customers to offer a competitive advantage in the marketplace.

Master Bond chemists have been diligent in designing conformal coatings with easy handling characteristics while emphasizing operator safety. Our highly effective coatings, available in a range of viscosities, provide excellent coverage over sharp edges to ensure uniformity and prevent surface defects such as irregular leveling and air bubbles. They prevent high voltage arcing, shorts, static discharge in miniaturized circuits and the need for enclosures.

Widely Used Master Bond Conformal Coating Systems

Single component, no mix UV light curing Master Bond UV10LV cures rapidly to increase throughput speeds. It exhibits outstanding dimensional stability, optical clarity and dielectric strength. Our UV/visible light curing compounds have tenacious bond strength and are widely used in outdoor weathering conditions. Specific grades such as Master Bond UV15DC80 have a secondary curing mechanism with moderate heat of 80°C for curing in "shadowed out" areas. Nanosilica filled Master Bond UV22 features enhanced dimensional stability, abrasion resistance and high Tg for advanced requirements.

MasterSil 713 one part silicone system has a viscosity of 2,000 ‘ 4,000 cps. This non-corrosive fast curing Master Bond conformal coating has superb flexibility/elasticity and is serviceable up to +400°F. It has been successfully tested for 1,000 hours at 85°C/85%RH for damp heat storage per Telecordia GR-1221 specifications. Master Bond Master Sil 152 is a two component system with a long pot life, low shrinkage and excellent optical clarity. This conformal coating compound can withstand rigorous thermal cycling, has a volume resistivity of >1014 ohm-cm and is highly resistant to water.

Our epoxy conformal coating EP37-3FLF is easy to use with a one to one mix ratio by weight or volume. Its low exotherm and elasticity lessens the stress on sensitive electronic components when curing. Master Bond EP37-3FLF is also noted for having outstanding impact resistance and light transmission properties. Chemically resistant Master Bond conformal coating EP41S-1 has gained popularity for its high strength, good flow and exceptional dielectric strength. This product has extraordinary resistance to solvents, fuels, alcohols, for service up to +300°F.

For additional information please visit our website at www.masterbond.com.

Share