Sprinter Marking Inc.

1805 Chandlersville Rd, Zanesville, Ohio, 43830 United States View map www.sprintermarking.comCoding & Numbering Machines

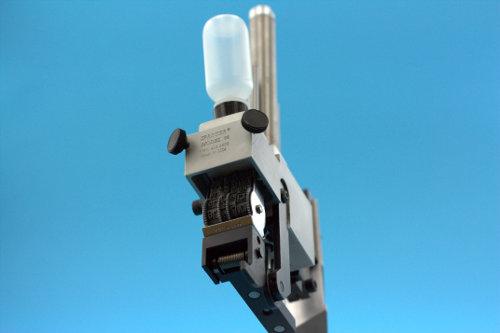

Sprinter Marking Inc. can provide coding and numbering machines that feature durability, versatility, and low maintenance requirements. We offer a range of contact ink-marking machine models that can provide automatic high-speed marking. They are used for a wide variety of applications such as dot/spot marking, product/date coding, lot/part numbering, and pass/fail marking. We can supply models for use in existing in-line production installations or standalone systems for off-line operations. Our machines can be mounted in any orientation and have a compact design so they can fit in confined spaces. We are the ideal source with our range of standard models and custom manufacturing capabilities.

Coding & numbering machines

Sprinter machines can be used on all types of surfaces including paper, plastic, glass, metal, cardboard, films, and rigid or flexible containers. Our machines can provide high quality markings whether the material is porous or non-porous, flat or curved, and stationary or moving.

Our machines can mark products with coding and numbering at high speeds ranging up to 350 cycles per minute depending on the model and surface being marked. They have low compressed air requirements thanks to small air cylinders, so most models can run on a minimum of 20 psi.

The different sizes of machines available can mark messages up to 2 square inches. The wide selection allows customers to get a model that meets their requirements and provides the lowest overall operating cost possible. Our machines have removable marking heads to allow quick message changes. Models are also available with indexable bands on the head that allow different characters to be "dialed in".

Company expertise

Sprinter Marking Inc. has been involved with ink code-marking machines for over 40 years. We can draw on this experience to analyze customers’ applications and provide the best solutions. For specific applications with unique requirements, we can provide made-to-order models. For example, in the past we have provided custom heads for marking tubular surfaces and split reservoirs for marking with two types of ink using the same motion of the marking head.

Durable construction

Our machines are built to last so they will provide reliable operation for several million cycles with minimal maintenance. For instance, the rods and bearings are hardened to minimize wear. In addition, the simple design and the patented reciprocating motion provide smooth action. They are backed up with a full one-year warrantee against any defects.

Share