Accumulating Conveyors

Norpak Handling Limited designs and manufactures accumulating and other conveyors. With facilities in Toronto and Vancouver, we provide top-quality equipment from coast to coast in only a few days. We specialize in automation and robotic projects, and also offer complete project integration. From system engineering and controls and programming to installation and service, our experienced and knowledgeable team can get your conveyors up and running in no time at all. We have forty years of experience, and are dedicated to helping you reach your material handling goals.

Accumulating Conveyors Product Line

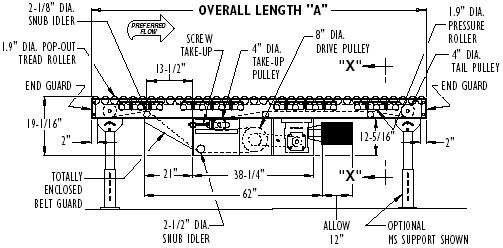

Our accumulating conveyors provide excellent general transport, and feature quiet operation, versatile design and require little maintenance. This chart documents the features of some of our most popular models.

| Product | Features |

| 138-ACC Light Duty (V-Belt) | –Basic design removes complex adjustments while allowing easy accumulation of cartons and boxes

–Minimum 2% back pressure –Max. load per linear ft. of conveyor: 50 lbs. –Bed: 6 ½” deep x 12 ga. formed steel channel frame powder painted –Rollers: 1 3/8” x 18 ga. galvanized tread rollers –Overall frame widths: 12”, 15”, 18”, 24” –No tools required for adjustment |

| 138-LRC Light Duty Curve (V-Belt) | –Live roller curves provides positive drive for negotiation 90º, 60º, 45º and 30º turns

–Self-powered or slave-driven –Bed: 6 ½” deep x 12 ga. formed steel channel frame powder painted –Rollers: 1 3/8” x 18 ga. galvanized tread rollers –Overall frame widths: 12”, 15”, 18”, 24” –Capacity: 150 lbs.

|

| 190-LRSS Medium Duty Straight Spur (V-Belt) | –Live roller spur conveyors suit diverging and converging applications

–Self-powered or slave-driven from ACC or LRC conveyors –Available in 30º and 45º spurs –Bed: 6 ½” deep x 12 ga. formed steel channel frame powder painted –Rollers: 1.9” x 16 ga. galvanized tread rollers –Overall frame widths: 16”, 18”, 20”, 22”, 24”, 26”, 28”, 30”, 34”, 36”, 40”, 42” –Capacity: 500 lbs. –Adjustable floor supports available

|

Accumulating Conveyors Industrial Applications

We serve a wide variety of market sectors, including the automotive, manufacturing, printing, food and beverage, and furniture industries.

Accumulating Conveyors Manufacturing Process

In addition to manufacturing a variety of conveyors, we provide numerous services to integrators of machinery, manufacturers, distributors and producers.

- Fill and seal operations

- Weigh and count operations

- Case sealing

- Bagging operations

- Labeling and marking applications

- Palletizing and de-palletizing

- Assembly line operations

- Paper products: cardboard box manufacturing, food grade packaging, slip sheet handling, banding and strapping operations

- Printing: carousel in-feed and discharge systems, roll handling systems, replenishment systems

- Food and beverage: bottle handling, freezer applications, case staging for routing or palletizing

Share