Industry embracing new possibilities with Festo’s revolutionary Motion Terminal

January 15, 2021Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Post your own REDWIRE news Subscribe

Free REDWIRE e-newsletter

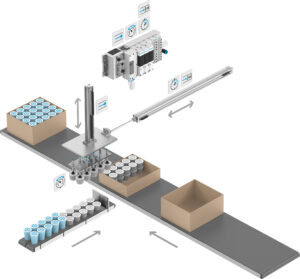

The Festo Motion Terminal (VTEM) uses software apps to set, control, and rapidly reconfigure all functions performed in both simple and complex pick and place solutions.

Mississauga, ON, January 2021 – As the standard-bearer for an entirely new type of pneumatics, the revolutionary Festo Motion Terminal (VTEM) is challenging engineers to re-imagine processes to capture some of its many economic and operational benefits. Just as the smartphone turned the mobile communications market on its head over a decade ago, VTEM’s digital pneumatics is capable of delivering sweeping upgrades to common automation processes like pick and place, dosing, machining and parts handling and assembly and much more.

Digital pneumatics is more precise and considerably more flexible than standard pneumatics. On a life cycle basis, it can perform many applications more efficiently and cost-effectively. VTEM software apps enable extremely fast changeovers for different sizes or shapes of workpieces, products or packaging. Adjustments that take hours with conventional pneumatics can be completed in minutes, and all processes can be managed, or reconfigured, remotely. The function integration achieved by software apps and the piezo valve technology in the Motion Terminal dispenses with the need for up to 50 downstream components – sensors, regulators, flow control valves, shock absorbers, and more.

The 11 available VTEM motion apps establish the parameters for functions such as proportional and directional valve control, proportional pressure control and selectable pressure levels, positioning, supply and exhaust air flow control, presetting time travel and soft stop. There also are apps for energy optimization and leakage diagnostics.

Here’s an example of how VTEM is streamlining automation in the real world. Autec, an Italian manufacturer of automation systems for shoe and leather goods factories, incorporated VTEM into a new machine for assembling credit card slots for wallets. The machine controls the gluing of two pieces, one leather, one silk. A servo robot then transfers the glued pieces to a leather-folding machine. In this space-saving, compact solution, eight credit card slots can be glued and folded in 14 seconds. The error rate associated with manually manufacturing these slots has been eliminated and optimum use is made of raw materials. “Reconfiguring the Festo Motion Terminal is now extremely fast,” says Ilario Barsacchi, project manager at Autec. “Instead of ordering, installing and reconfiguring additional proportional valves, all we have to do is activate an app.”

The app enables a fast change in the tool function from suction gripper head to gripper head with pin terminal as the piezo valves can be used both as proportional valves and as control valves. The system is then just like a reprogrammable piece of hardware and the software content is adapted to the relevant application. The days when a valve only had a single function are over. The system is just like an easily reprogrammable piece of hardware.

Motion apps give designers a great deal of freedom. With all that VTEM offers, there is no limit to what designers can conceive of to make automated systems better and Industry 4.0-ready.

Festo at a glance

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation. In Canada, Festo has been supporting Canadian industry for over 40 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support. Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology. In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions. The Festo Group registered sales of around €3.07 billion in the 2019 financial year and is represented worldwide at 250 locations with 21,000 employees. About 8% of its annual turnover is invested in research and development.

| For inquiries: | |||

| Natasha Gosine

Festo Canada Phone: 905-614-4611 Mobile: 647-622-2689

|

Martin Wendland

PR Toolbox Inc Phone: 416-368-6636 Mobile: 011-49-160-99127473

|

||

| Festo in Social Media: | |||

| www.facebook.com/FestoCanada | |||

| www.twitter.com/FestoCanada | |||

| www.linkedin.com/company/festo-canada | |||

| Youtube | www.festo.com/youtube | ||

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more