A & M Heat Treating Ltd.

1815 Drew Rd, Mississauga, Ontario, L5S1J5 Canada View map www.amheattreat.comCarbonitriding

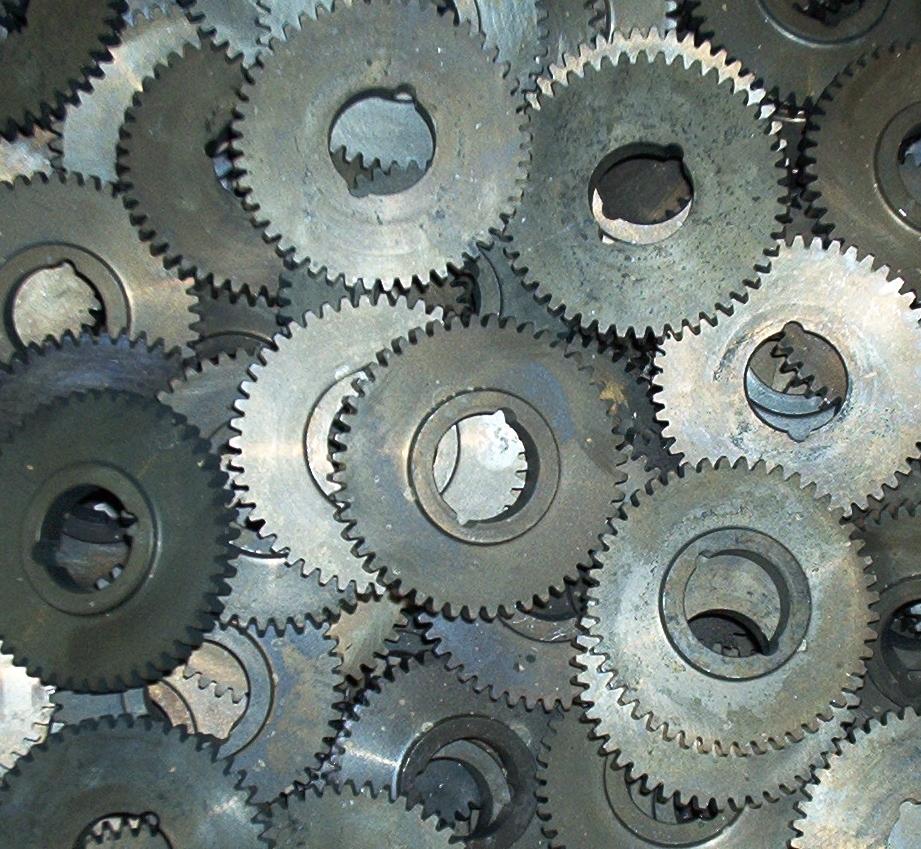

Since 1994, A&M Heat Treating Ltd remains a leading provider of vacuum heat-treating services. You can rely on us to deliver top productivity and performance in specialized carbonitriding service. We are heating experts with the right surface engineering technologies to effectively heat a variety of metals for specific products such as various gears and shafts, rollers and bearings, pistons, and levers, to name just a few. Products with hydraulic and actuated systems of mechanical and pneumatic properties are best served with the carbonitriding process.

A variety of industries served

A&M Heat Treating Ltd. carbonitriding serves a diverse number of industries including automotive, aerospace and defense, energy, hot isostatic processing, general industrial and more. Metals that are best suited to carbonitriding are plain carbon steel grades, AISI 1010 through 1020. This process adds bulk carbon content to a metallic surface as high as .4 to .5 per cent to an ideal case hardened depth of approximately 0.7mm. Our modification process at A&M Heat Treating adds ammonia to methane or propane to modify gas to harden internal metal components. Carbonitriding is just one of ten specialized methods of heat processing that we offer our customers.

Specialized innovative process

Our carbonitriding process modifies the surface metal effectively to an extreme heat controlled temperature between 760 to 870 degrees Celcius and in a standard gaseous atmosphere of between 0.5 to 0.8 per cent carbon and .2 to .4 per cent nitrogen. The benefits of carbonitriding, versus other processes of metallic heating at lower temperatures such as nitriding, are improved wear resistance, and strength under high fatigue to plain carbon steels that require a thorough-hardened core. Some mild steels such as those with reduced aluminum content and low allow steels with free cutting, sintered steel and carbon content at a maximum of 25 per cent. Carbonitriding is an effective cost-efficient way of heat-treating a wide variety of small components in single or large production run orders.

Excellent in-house processes and customer service

A&M Heat Treating is a respected leader in the heat treating industry as a service provider and processing expert. Get in touch with our team of in-house heat-treating experts to get a free quote for any of our specialized services including carbonitriding, or to inquire directly about the treatment process. Our wide range of metal treating services also include vacuum heat treatment, carburizing, solution annealing, salt bath treatment, precipitation aging, normalizing, stress relieving, cryogenics, metallurgical laboratory service, case hardening, cryogenic treatment, deep freezing, nitriding, normalizing, quelching and more. We aim to exceed customer expectations and reach our vision of delivering a large selection of metal heat-treating solutions to keep up with the increasing demands of new and innovative technologies.

Share